Spray Drying

Panoramica Dei Concetti di Base

Altri articoli sulla micronizzazione:

Siamo specializzati nella micronizzazione di integratori con spray dryer per prodotti ad alta biodisponibilità.

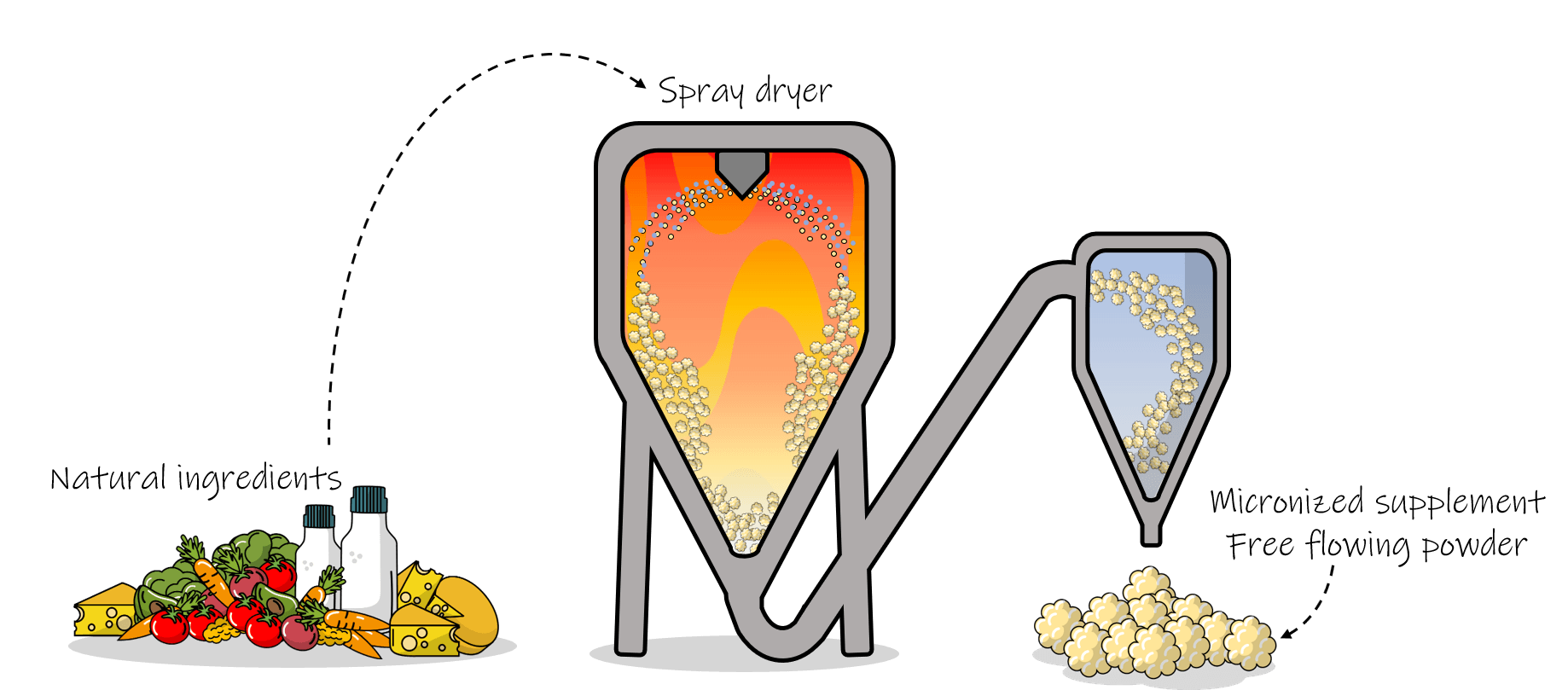

Lo spray drying consente la produzione di integratori micronizzati sottoforma di polveri costituite da migliaia di micro particelle amorfe. La trasformazione in polveri micronizzate offre numerosi vantaggi che vanno dal miglioramento della stabilità del prodotto fino all’aumento della flessibilità di stoccaggio, trasporto produzione della forma di dosaggio finale. Questo articolo fornisce una panoramica dei concetti di base, delle considerazioni chiave e dei vantaggi quando questa tecnica viene applicata agli integratori.

In questo articolo illustreremo i passaggi fondamentali della micronizzazione con spray dryer per gli integratori.

Il processo di spray drying

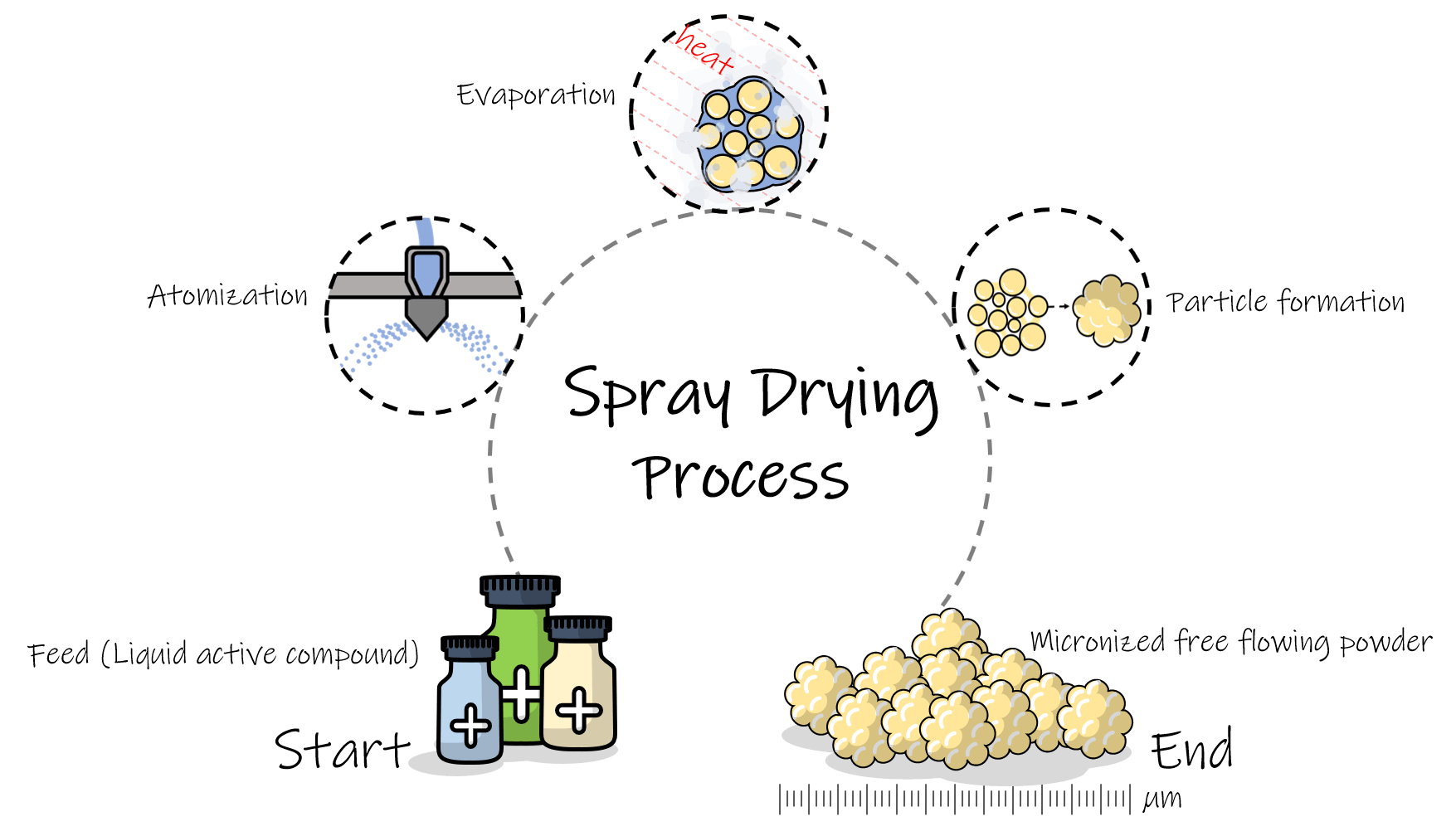

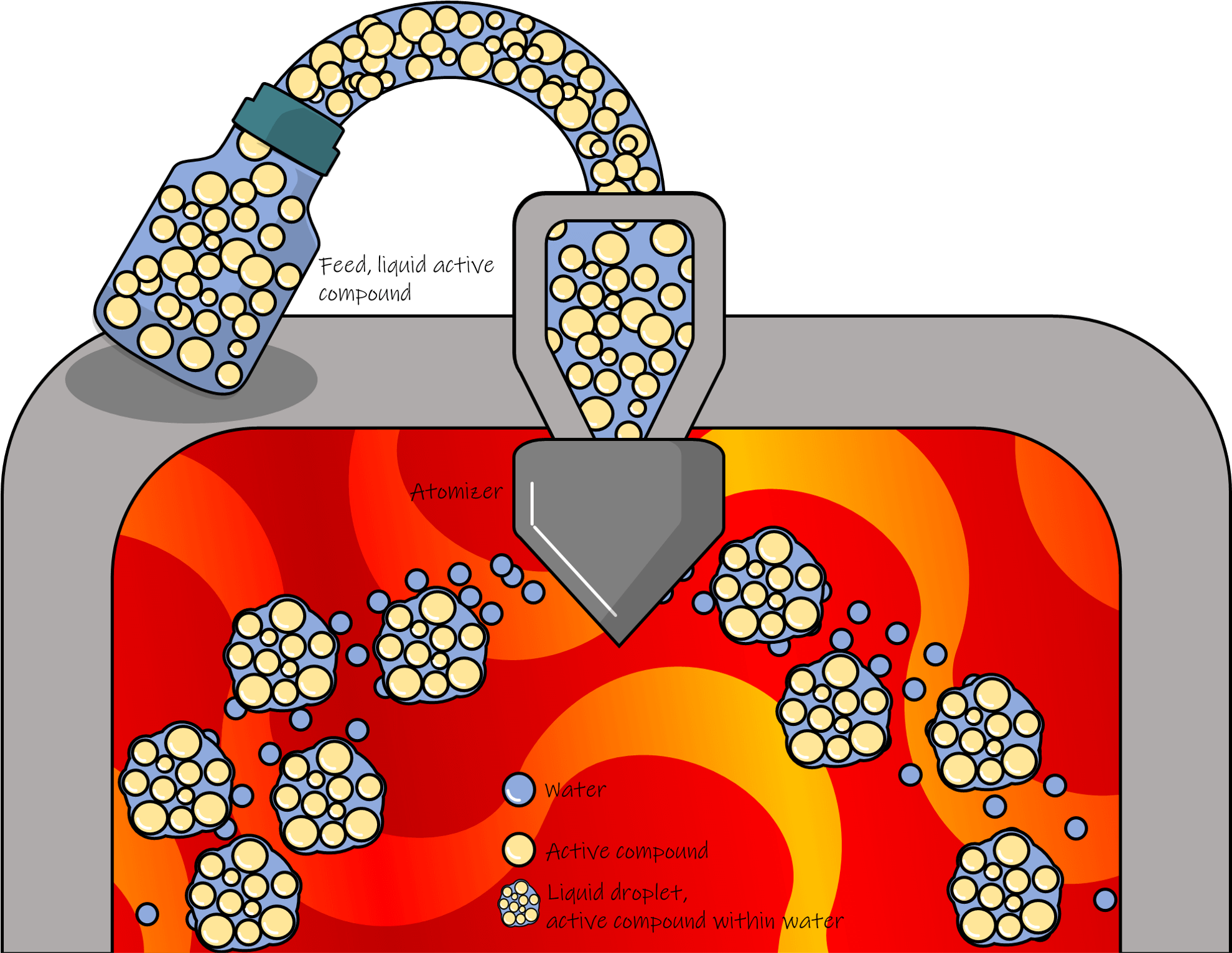

Lo spray drying è un processo di micronizzazione in cui una formulazione liquida, chiamata alimentazione (feed), viene trasformata in una polvere secca attraverso un processo termodinamico schematicamente suddivisibili in 3 fasi:

- Atomizzazione

- Evaporazione

- Formazione delle particelle

Atomizazione

Il processo inizia con l’atomizzazione dell’alimentazione (feed) che viene forzata attraverso un ugello che la riduce in goccioline microscopiche, e ha lo scopo di aumentare il rapporto area superficiale/volume del liquido. L’ugello può essere di diversi tipi: a pressione, rotativo o a due fluidi.

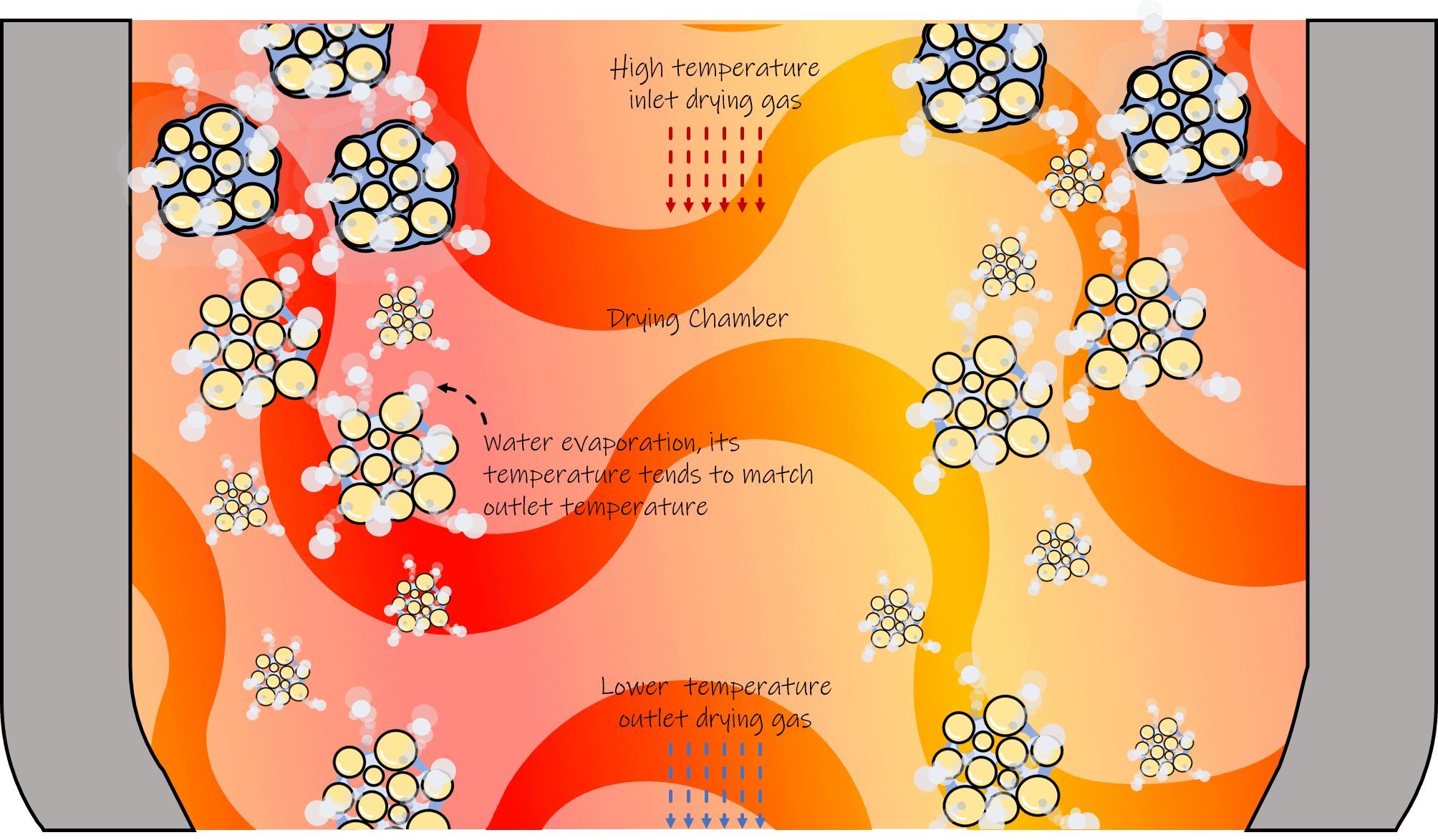

Evaporazione

Una volta formate, le goccioline atomizzate sono esposte al flusso ad alta temperatura del gas essiccante. Lo scambio di calore tra il gas e le goccioline induce in queste sia un aumento di temperatura della componente solida che un cambiamento di stato della componente liquida in vapore, favorito dall’elevato rapporto area superficiale/volume indotto dall’atomizzazione.

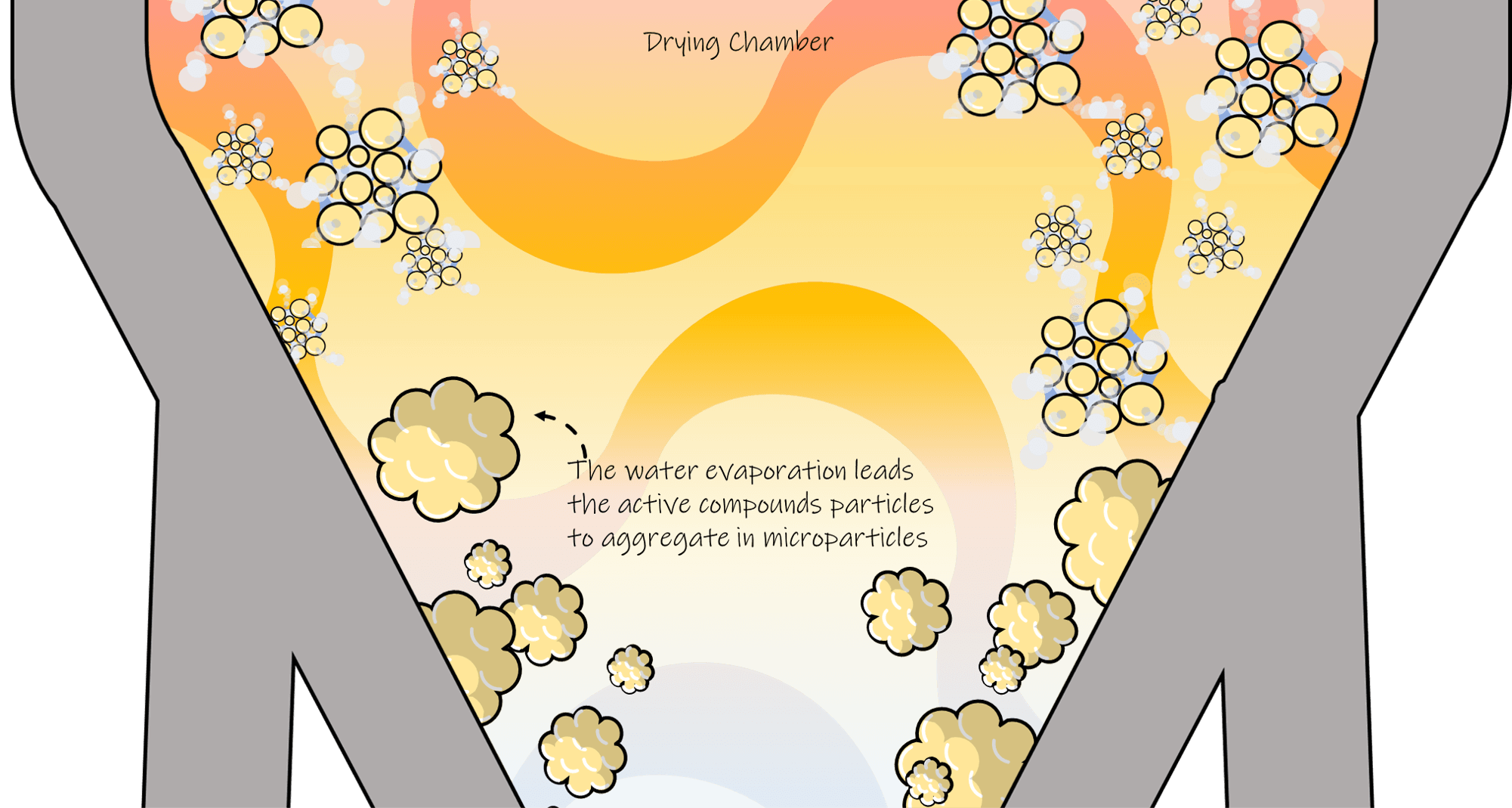

Formazione di particelle

Man mano che il liquido evapora dalle goccioline, la componente solida inizia a interagire e a formare le particelle solide. Le caratteristiche del prodotto finale, come dimensioni, morfologia e densità, sono influenzate da tali interazioni e queste dai parametri di processo come la composizione dell’alimentazione, la temperatura e la portata del flusso del gas essicante.

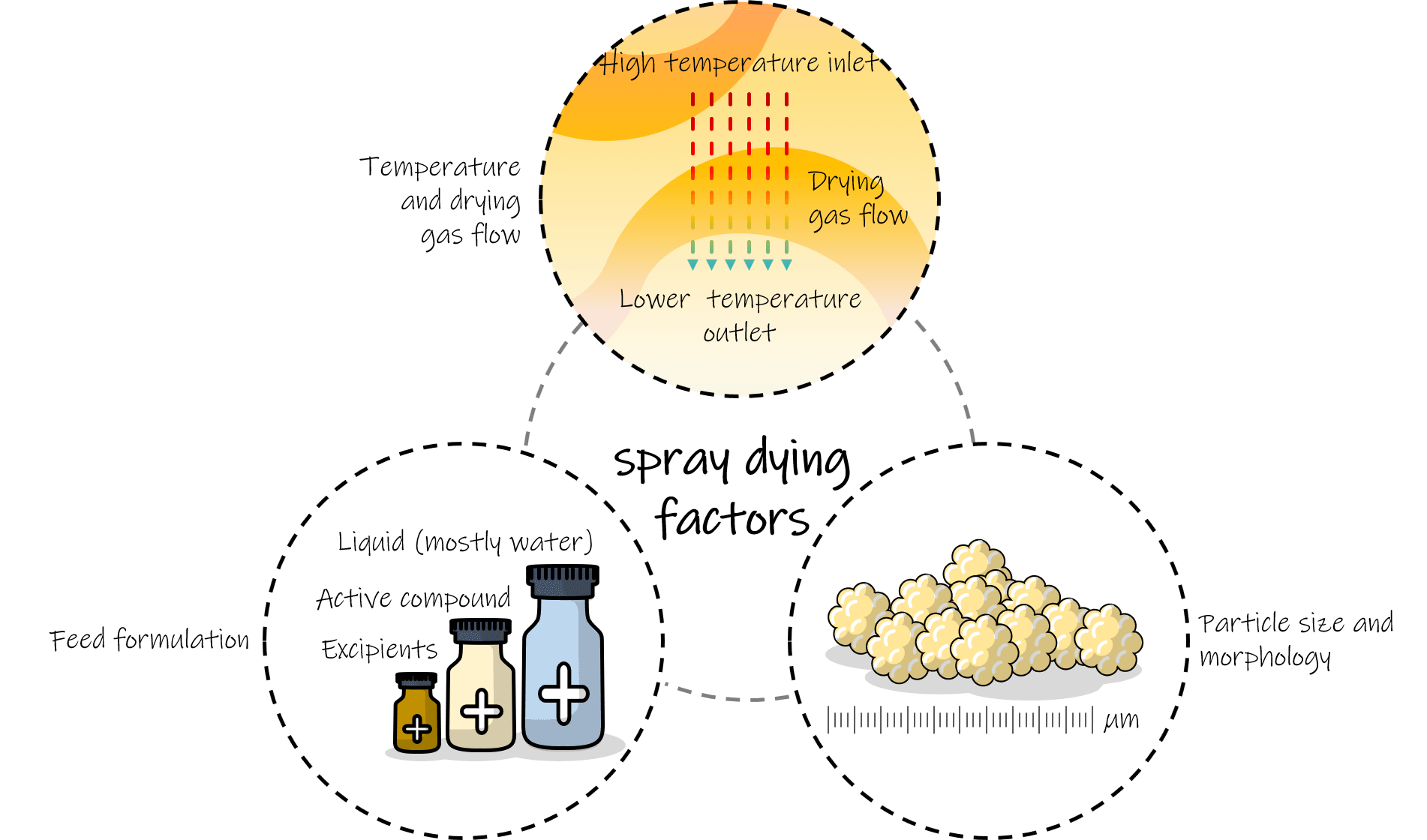

Considerazioni sullo spray drying

I fattori che intervengono nel processo di spray drying e nella produzione di integratori ad alta biodisponibilità:

1. Formulazione del liquido di alimentazione (feed)

2. Temperatura e flusso del gas di essicazione

3. Dimensione e morfologia delle particelle

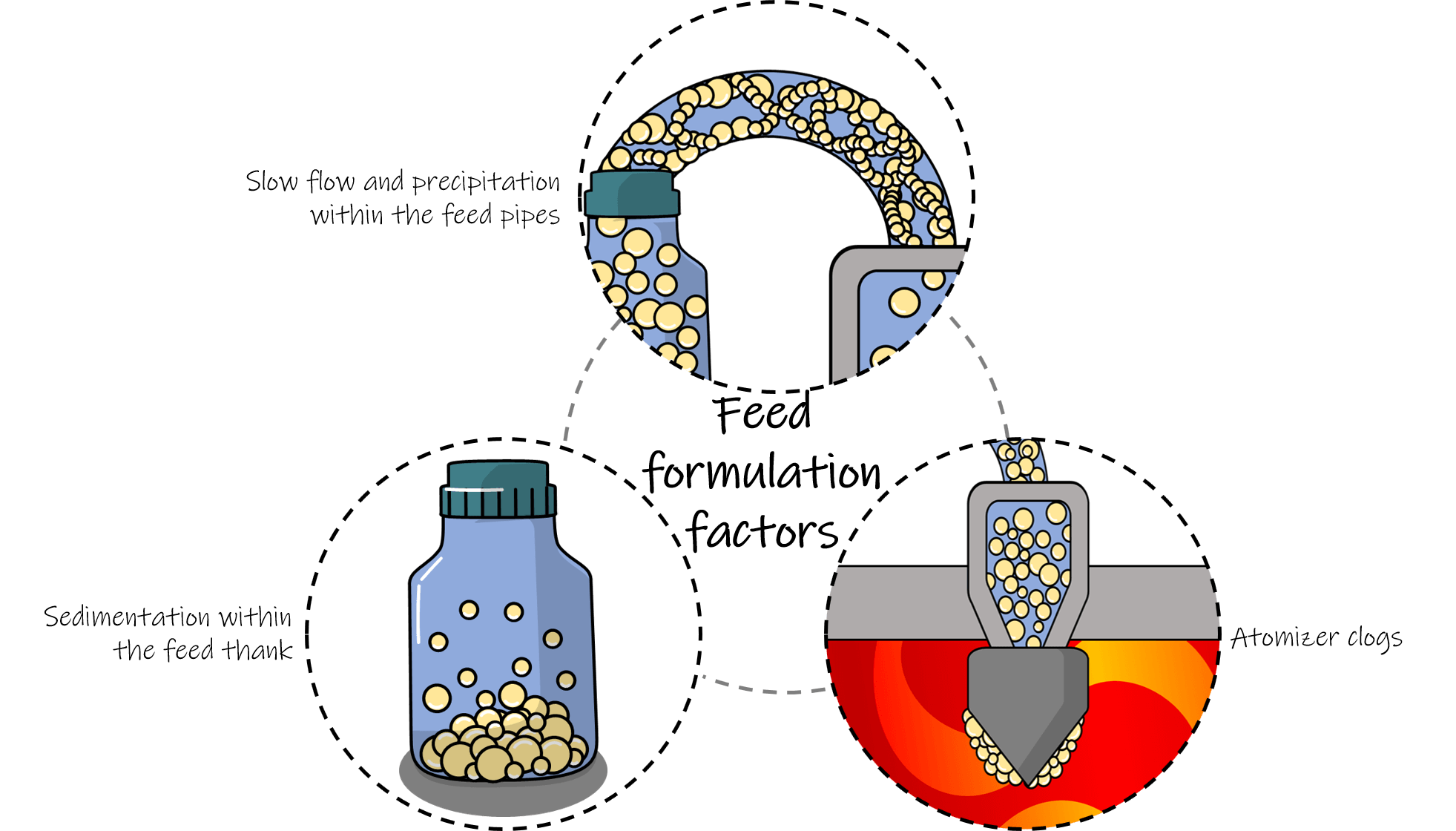

Liquido di alimentazione

Quando si formula il liquido di alimentazione (feed) bisogna prevedere il suo comportamento durante il processo di essiccazione, ovvero evitare sia che la componente solida si aggreghi, che la sua viscosità non ne impedisca il passaggio attraverso l tubature che portano all’ugello e di non introdurre eccipienti sensibili alle temperature di esercizio, pena la compromissione dell’efficienza del processo.

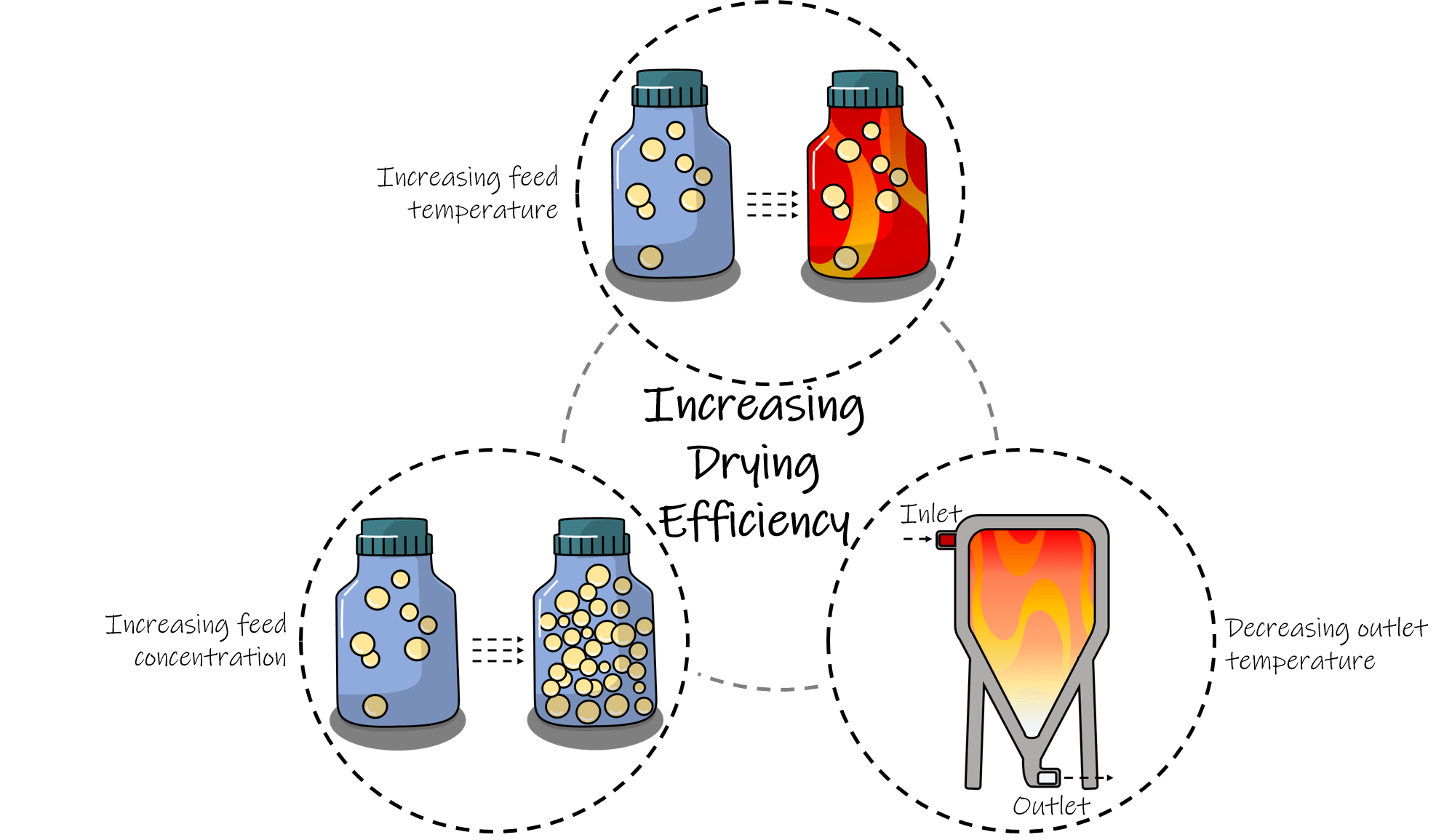

Efficienza di essicazione

Mettere a punto un processo efficiente è importante per assicurare la consistenza della qualità in tutti i lotti e costi di produzione contenuti.

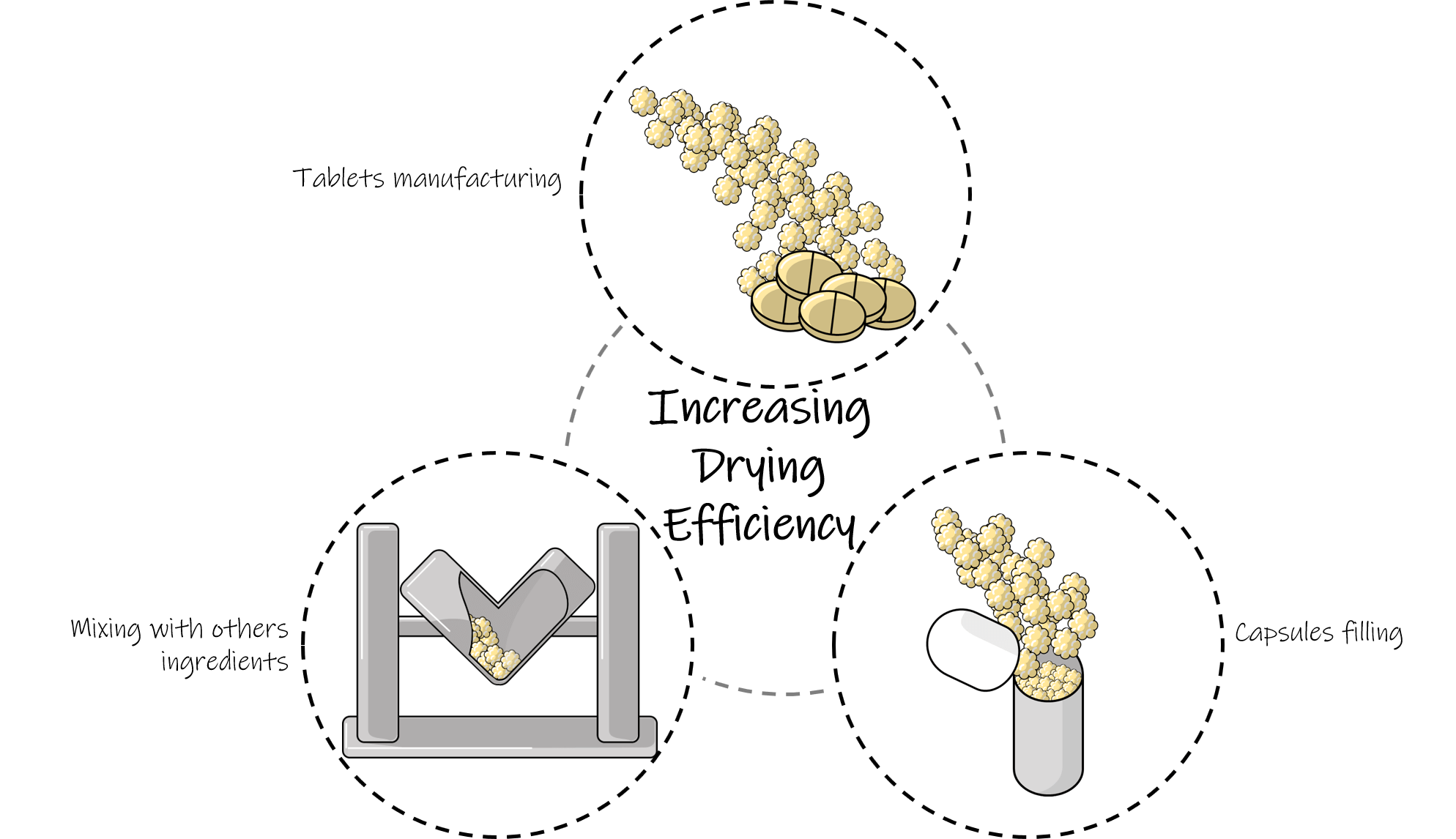

Dimensione e morfologia delle particelle

La dimensione e la morfologia delle particelle influenzano sia la scorrevolezza che il rapporto area superficiale/volume delle microparticelle. La scorrevolezza della polvere è importante nelle ulteriori fasi di lavorazione come miscelazione, compressione o incapsulamento. Il rapporto area superficiale/volume è proporzionale alla liberazione del composto attivo dalle microparticelle e quindi all’efficacia del prodotto.

Conclusione

Lo spray drying è una tecnica capace di produrre integratori micronizzati in microparticelle amorfe con elevato rapporto superficie/volume che comporta il miglioramento della biodisponibilità del prodotto. L’ottimizzazione dei parametri di tale processo è razionalizza i costi di produzione e minimizza la varianza delle caratteristiche tecnologiche lungo i vari lotti di produzione.

Technology Scientific è la PMI nata spin-off Serviamo le migliori companies and startups

GUIDA PDF GRATUITA

La guida completa alla

progettazione di processi di micronizzazione di integratori

La guida definitiva e gratuita per progettare,

realizzare e lanciare il tuo integratore micronizzato.

Con le micronizzazioni di Technology Scientific,