Spray Drying

An Overview of Basic Concepts

Other articles about micronization:

We are experts of in micronization of supplements and micro delivery systems for supplements with high bioavailability.

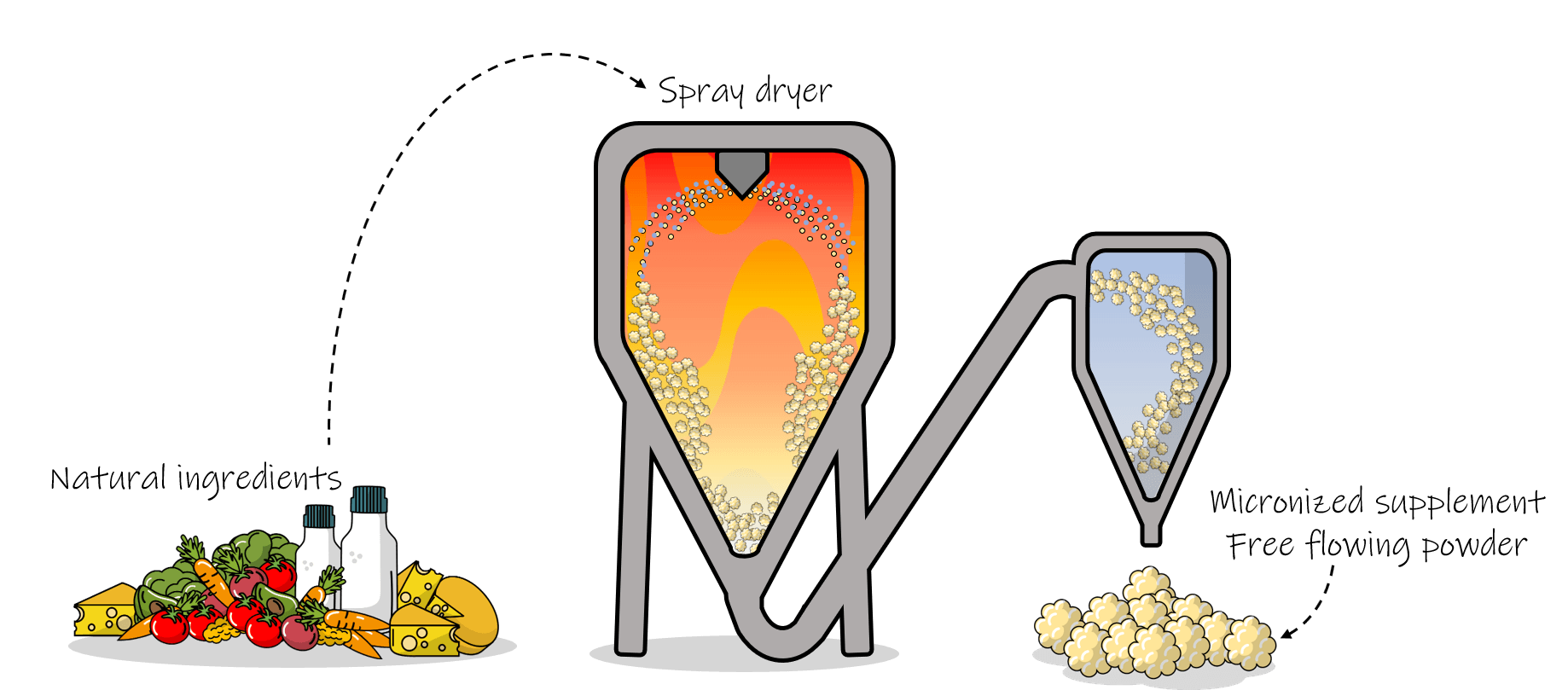

Spray drying is a widely utilized technique for the production of powdered supplements made of thousands of amorphous micronized particles. The process offers several advantages raging from preservation of the nutritional value of the most heat sensitive compounds, improvement of the product stability, increase of storage time and transport flexibility. This article provides an overview of the basic concepts, key considerations, and benefits when this technique is applied for supplements.

In this article, we'll outline the steps during the micronization with spray dryer of supplements.

The Spray Drying Process

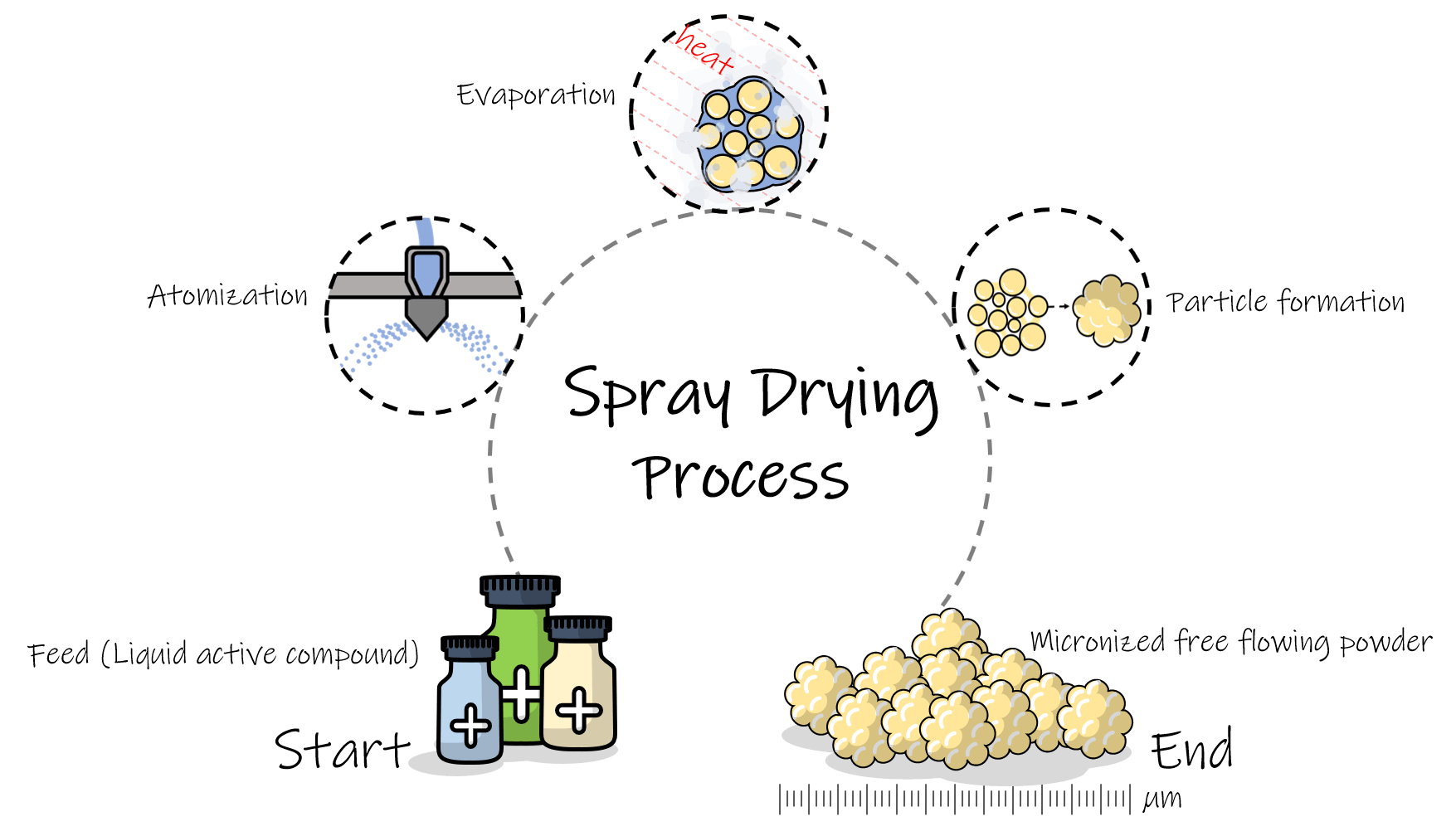

Spray drying is a micronization process in which a liquid formulation, generally called the feed, is transformed into a dry powder through a thermodynamic process schematically divided in 3 phases:

- Atomization

- Evaporation

- Particle formation

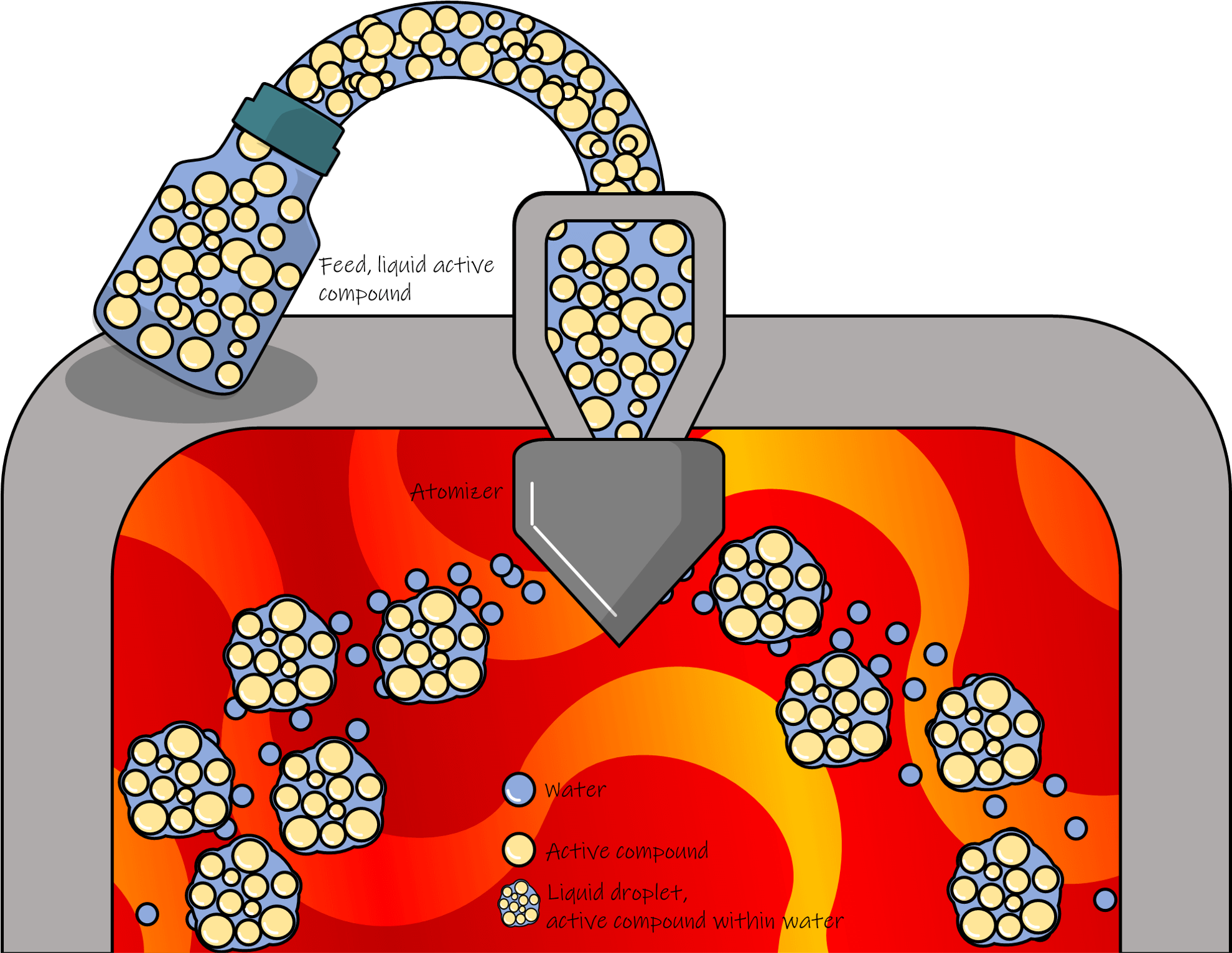

Atomization

The feed is atomized into fine droplets by a nozzle, increasing the surface area of the liquid and increasing the drying speed. The nozzle can be of several types: pressure, rotary, or two-fluid.

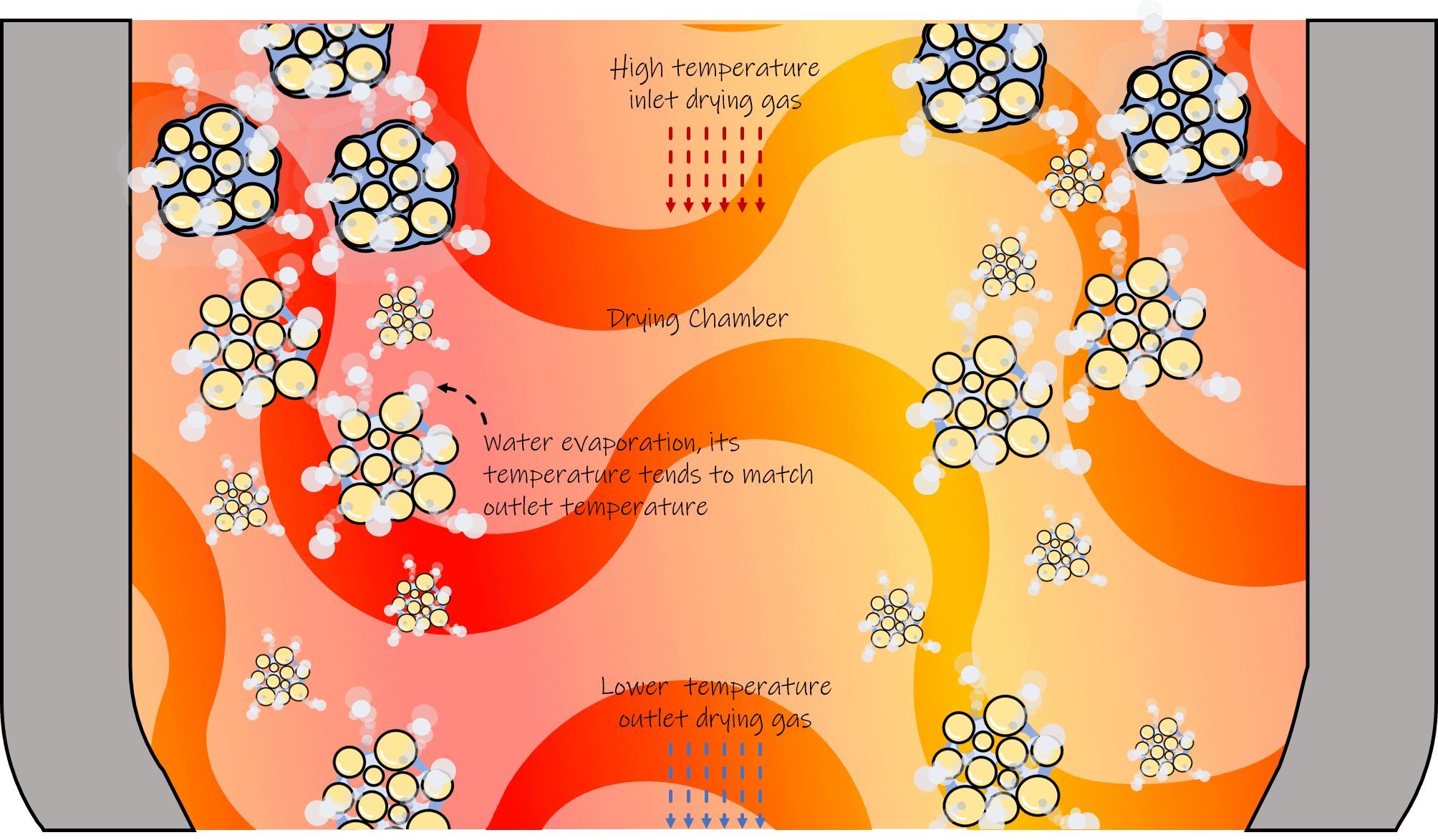

Evaporation

The atomized droplets are formed within the drying chamber, in which a hot-drying gas stream exchange heat with the droplets using it either to increase their temperature and to induce a quick evaporation of the liquid component.

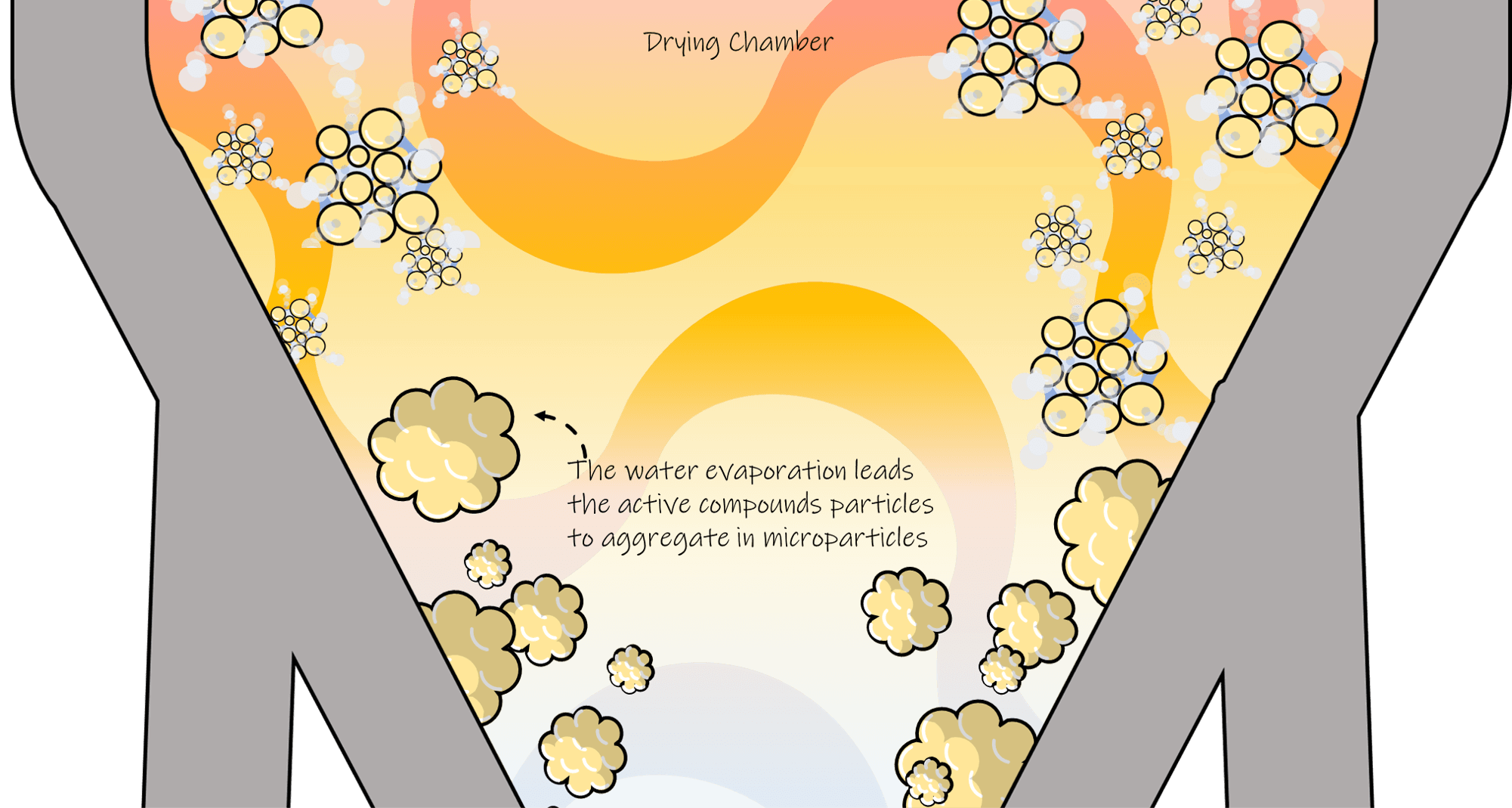

Particle Formation

As the liquid evaporates from the droplets the solid component starts to interact and to form the solid particles. The characteristics of the final product such as size, morphology, and density, is influenced by processes parameters as feed composition, dry gas inlet temperature and flow rate.

Key Considerations in Spray Drying

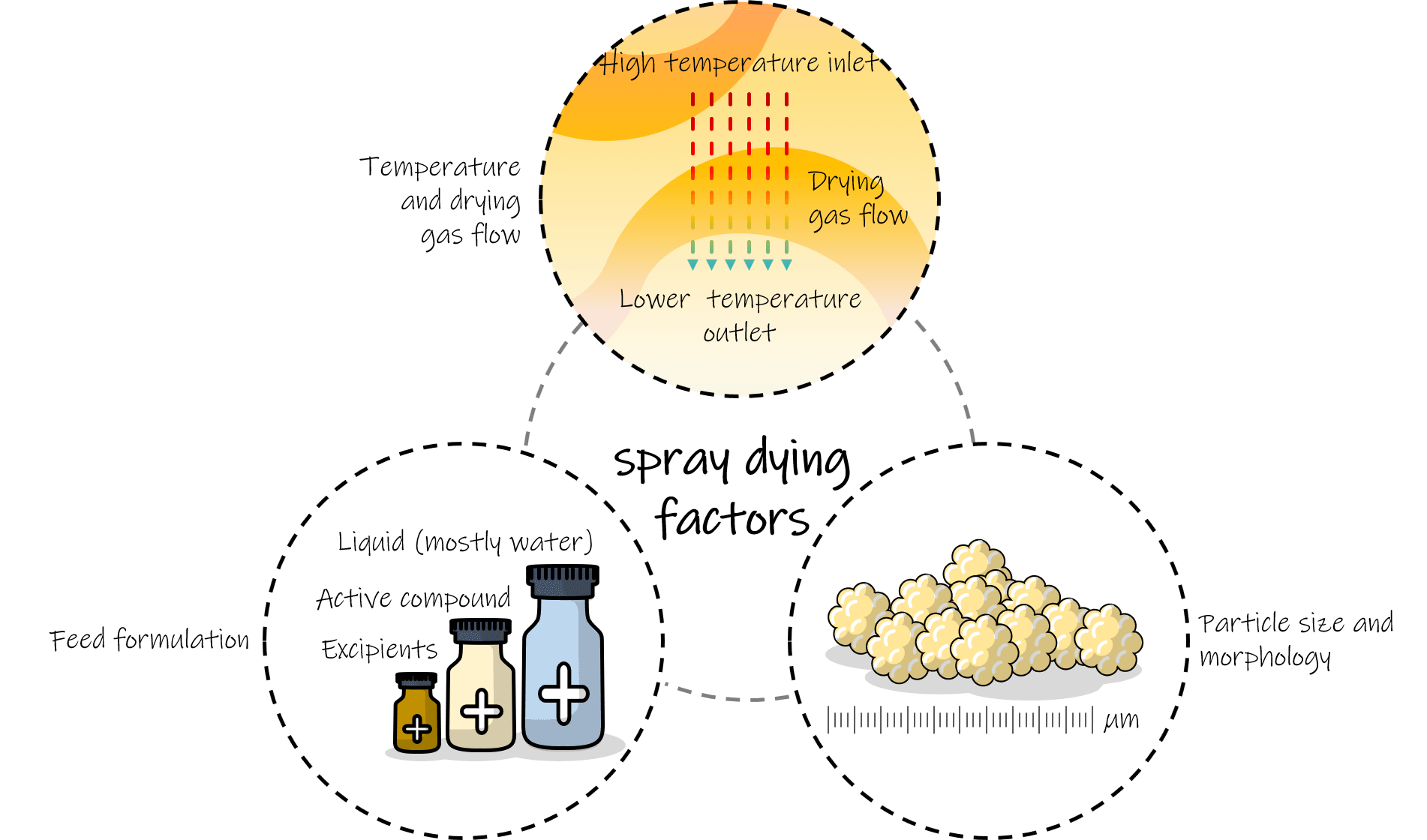

Key factors for a successful spray drying micronization:

1. Particle Size and Morphology

2. Feed Formulation

3. Temperature and flow rate of the drying gas

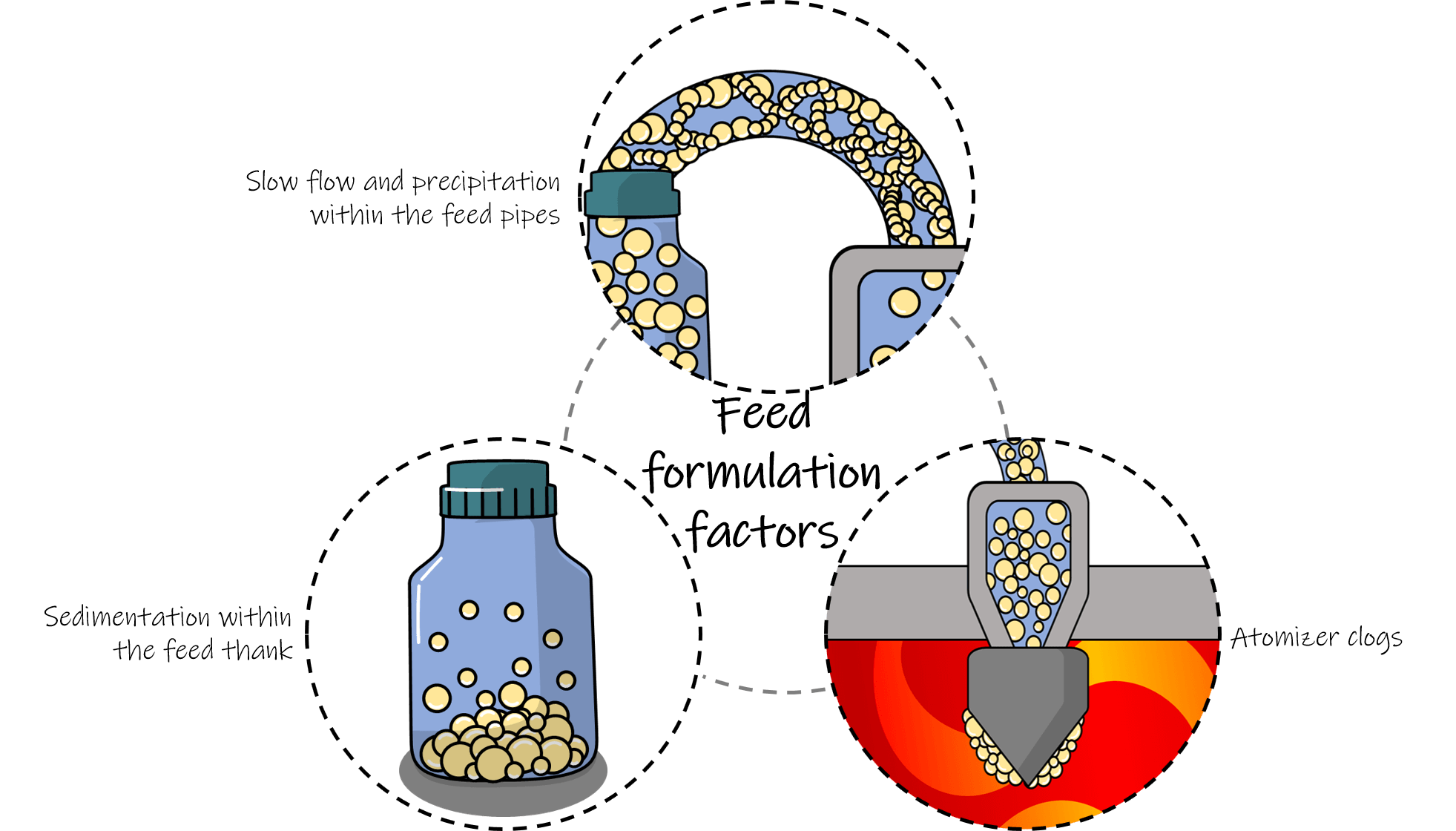

Feed Formulation

When preparing the feed it has to be considered how it will behave during the drying processes avoiding aggregation, high viscosity, and heat sensible components. If one these is overlooked the efficiency of the drying processes is compromised.

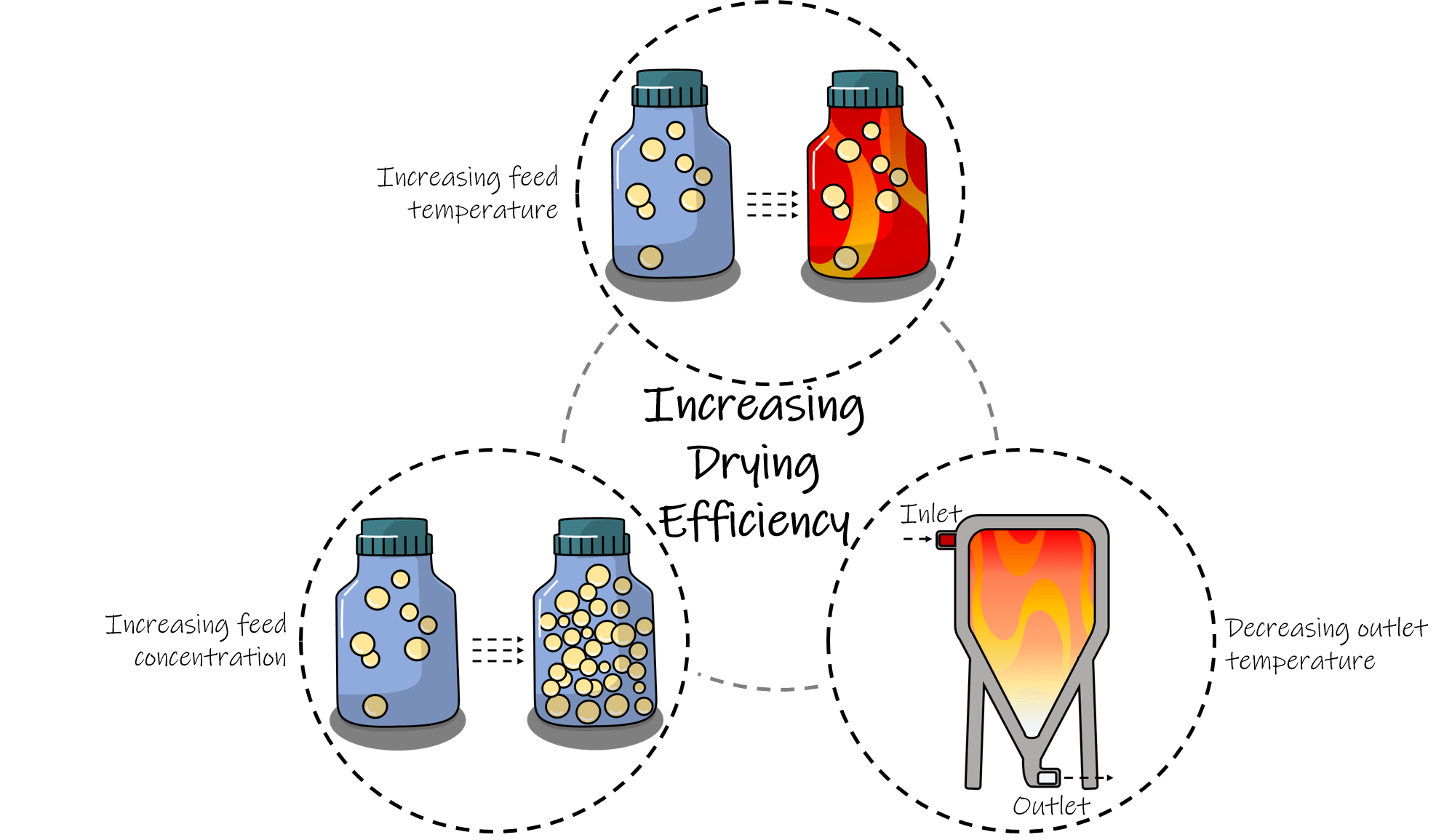

Drying efficiency

The efficiency of the drying processes is directly linked to the final production costs and quality consistency across the butches.

Particle Size and Morphology

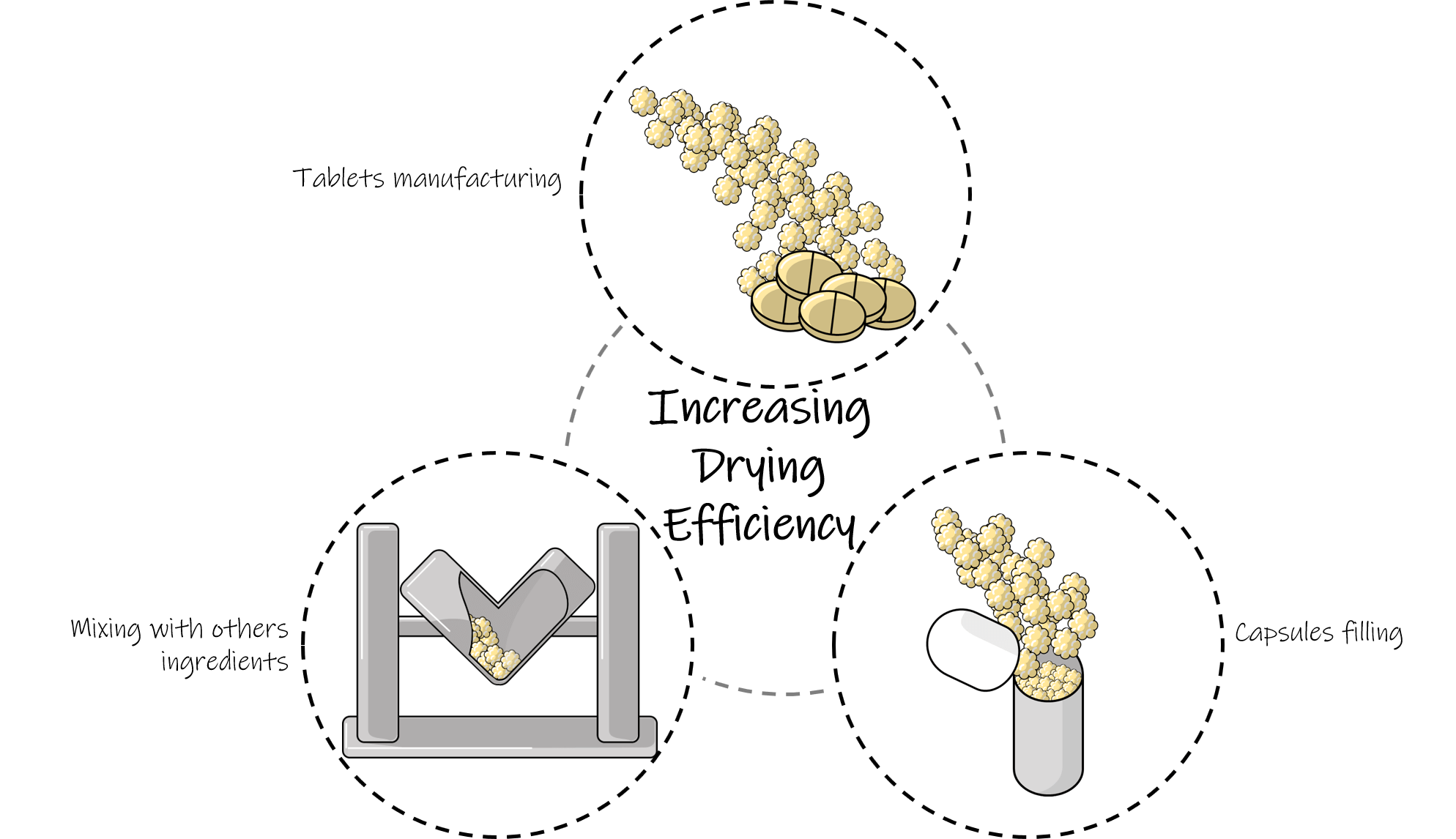

Particle size and morphology influence the microparticle rate surface-area/volume, bulk density and porosity, which are linked to powder flowability and dispersibility, important for the further processing as mixing, compression or encapsulation. While microparticle surface-area/volume rate is an important parameter to regulate the active compound liberation, which is linked to solubility and bioavailability.

Conclusion

Spray drying is a valuable technique in the production of powdered supplements and the comprehension of its basic concepts unsure a successful transformation of classic products into highly effective supplements actually improving their well-being. A masterfully optimized micronization process also allow supplement companies to produce at lower costs and market higher added value products.

Technology Scientific is the SME born as an

academic spin-off

We serve top companies and startups

top companies and startups

FREE PDF GUIDE

The Complete Guide to

craft a successful innovation plan for supplement micronization

The ultimate and free guide to easily design an innovation project for supplement micronization, proven to increase the bioavailability and efficacy of your products.

With Technology Scientific micronization,