We are experts of in micronization of supplements and micro delivery systems for supplements with high bioavailability.

Many micronization providers are reluctant to share the limitations of their micronization services, and this may increases the risk for you of developing a micronized product at higher cost, longer development time and that offers fewer health benefits

Before you consider a micronization provider, you should define your goals and choose a the provider based on their advantages and limitations fit your goals.

At Technology Scientific, we believe in open sharing of strengths and weaknesses to select only the most promising collaborations, allowing you and us to carefully choose the best partners.

Nothing is perfect, and while we are proud of our micronized products, we recognize that they may not be suitable for everyone, including you.

That's why we wrote this guide to help you assess if you are a good candidate for our services.

The importance of defining goals:

To increase the solubility

If you want to micronize to increase the solubility, simply reducing the particle size of the ingredients may be sufficient (read more on how the micronization increase the surface-area to volume and thus the solubility). in In this case, the development of the micronized product will be relatively simple and does not require a preformulation study. It can be carried out directly at the final manufacturer through a pilot production.

However, if you want to verify that the micronization has actually been useful, you should test the new product with a solubility study. In this case, the manufacturer may not perform such studies in their facilities, which forces you to contact a laboratory to verify the possible increase in solubility.

If the increase is not satisfactory, a formulation study that, for example, includes an amphiphilic excipient to enhance the solubility, than is necessary. In this case, the development cost increases due to the addition of the formulation study.

To increase the stability

The same applies to the stability: simple micronization could be enough to increase flowability, improving miscibility and decreasing segregation, with positive effects on stability. If this increase is not sufficient, a formulation study could add excipients with antioxidant or protective function or produce a microparticle with core-shell structure with the shell protecting the core from degradation.

To improve the machinability

To improve the flowability for machinability, a simple micronization may be sufficient. Otherwise, rather than a formulation study, we suggest to proceed with a more cost-effective change of the flow agent (silica or cornstarch) during processing. Finally, if this does not work a formulation study, could alter surface property of the micrparticles increasing their flowability. In any case the formulation will have some unwanted side effect as the increase of the dosage form size, which could potentially decrease the compliance.

To improve the palatability

Improving the palatability requires a formulation study to verify the compatibility of the excipients and the required quantities. These studies generally do not pursue complex technical objectives and are relatively inexpensive.

New delivery system for supplements

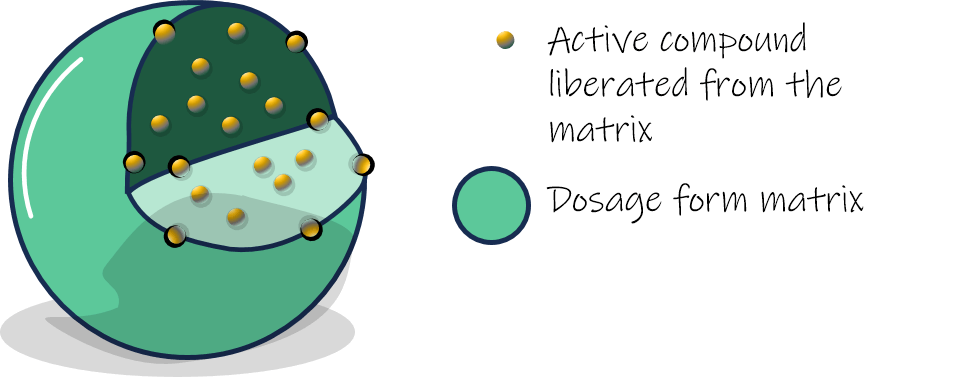

On the other hand, if you want to develop a new supplement that can maximize the biological effect of the active ingredients, then what you need is a delivery system for supplements. The formulation study in this case becomes central and will considerably affect both the cost and the added value of the new product. It will last several months and will develop a technologically advanced supplement, a micronized powder made up of thousands of microparticles, each capable of acting as an independent micro delivery system. This delivery system can protect the active ingredients from gastric degradation, concentrate their release at the absorption site, promote membrane permeation and control their release rate so that the supplement is active throughout the day, decreasing daily administration and increasing compliance.

Conclusion: are we the right partner?

We are not the right partner if you do not need a formulation study and at the same time need to produce large quantities (i.e. > 2000kg). In this case, a manufacturer with a production capacity of >100kg/day is more suitable and will be able to offer you the necessary support for micronization that does not aim for a technologically advanced product. You will most likely need to outsource some of the analysis, such as solubility and efficacy studies, to another laboratory.

We are the right partner for you in al other cases, whether you need:

- A micronization capable of transforming the therapeutic potential of your supplement into a sensible health improvement for the people.

- A micronization accompanied with rigorous data to fuel a convincing marketing campaign.

- A partner able to perform all stages from development to production.

Technology Scientific is the SME born as an

academic spin-off

our innovation services are used by

top companies and startups

FREE PDF GUIDE

The Complete Guide to

craft a successful innovation plan for supplement micronization

The ultimate and free guide to easily design an innovation project for supplement micronization, proven to increase the bioavailability and efficacy of your products.

With Technology Scientific micronization,