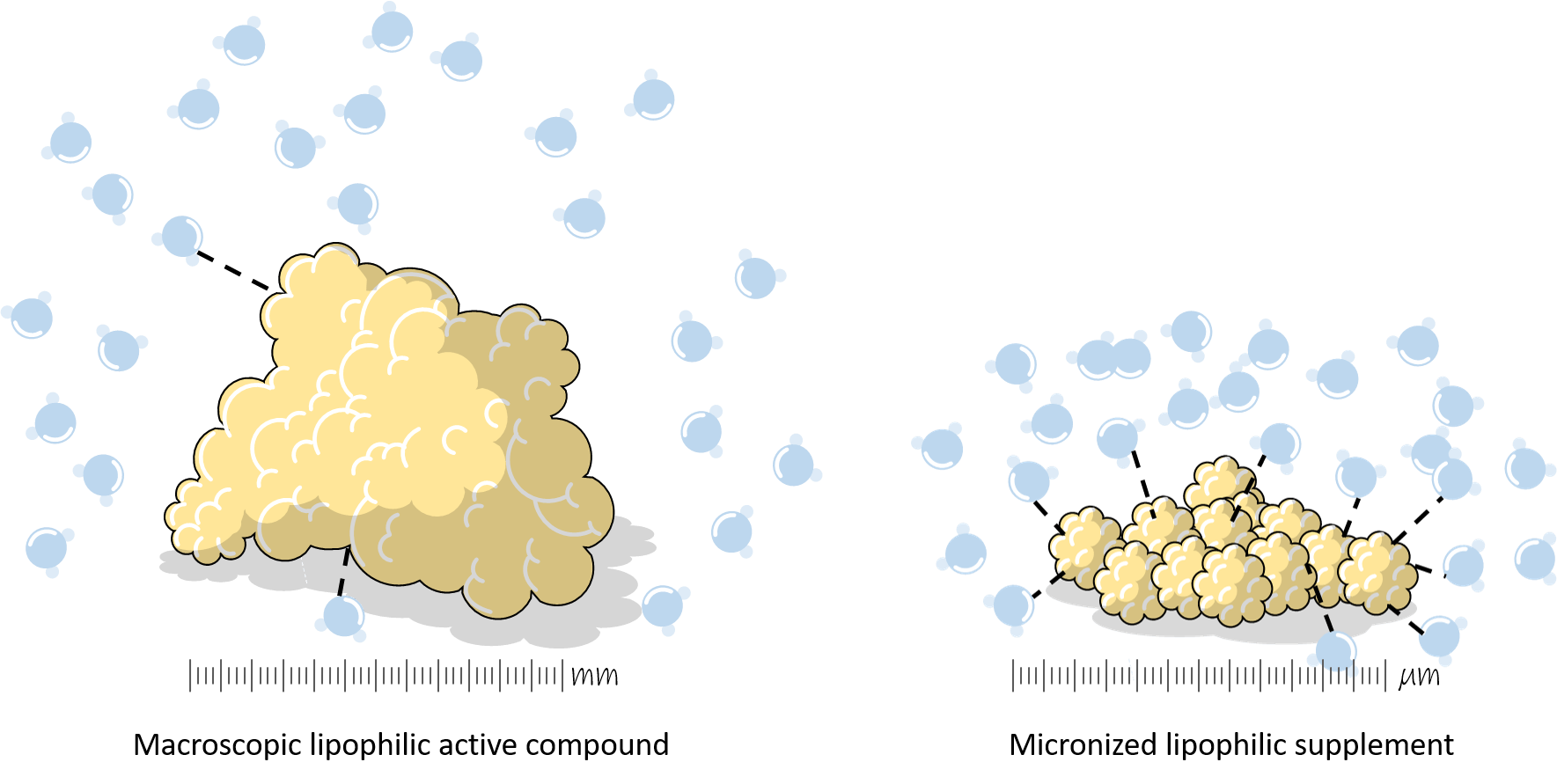

We are experts of in micronization of supplements and micro delivery systems for supplements with high bioavailability.

The cost of micronization can be a barrier for some companies. The problem is that most providers are often reluctant to share their pricing policies.

At Technology Scientific, we understand the importance of transparent and comprehensive cost breakdowns, and for this reason, we have prepared this guide to explain how companies calculate prices for supplements micronization projects. So that you can make the best-informed decision and get the most out of your investment.

This article will explore the factors that influence the cost of micronization and provide tips for optimizing it.

Understanding the four components influencing the cost of a supplement micronization project

Process development

The complexity of the micronization process varies depending on the product characteristics and the desired objectives. A more complex process requires longer development times and therefore a higher cost. In a supplement micronization project aiming to provide micronized delivery system for supplement, this may contribute to the 10-30% of the final price.

Labour, equipment & Materials

Micronization requires specific skills, a dedicated team, and the use of sophisticated equipment. The amount of man-hours, the use of costly testing and materials depend on the number of project objectives and how challenging they are. In a supplement micronization project aiming to provide micronized delivery system for supplement, this may contribute to the 20-40% of the final price.

Validation of efficacy

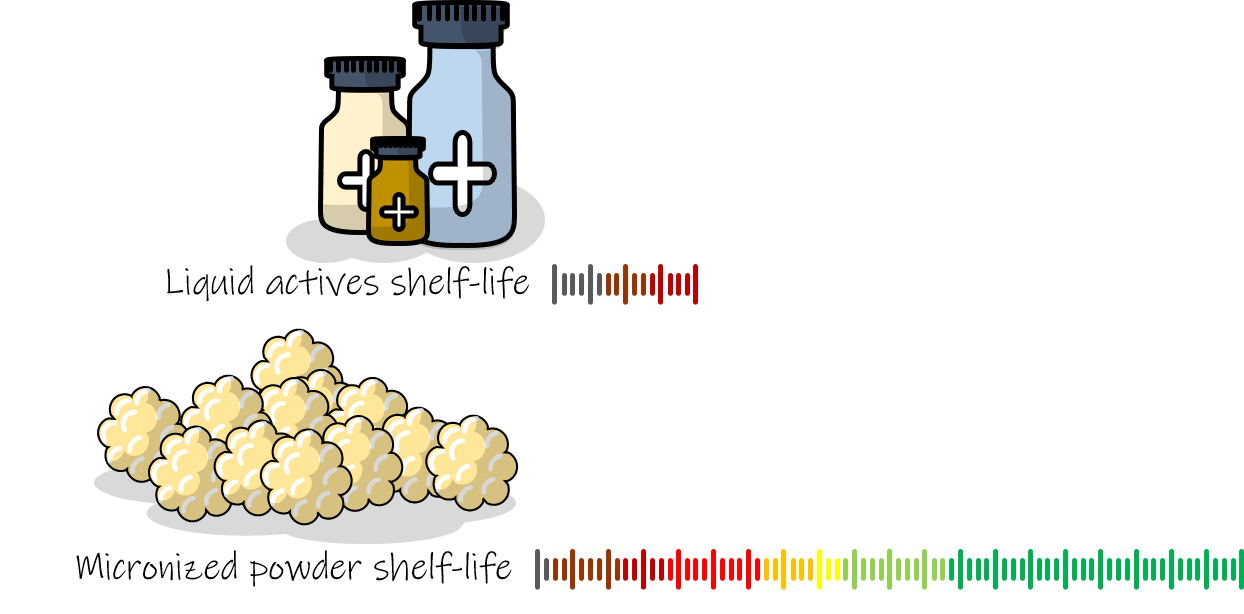

The success of the micronization needs to be verified with a rigorous testing campaign aiming to validate the efficacy of the new micronized product through enzymatic, dissolution and permeation tests, bioavailability studies and shelf-life. In a supplement micronization project aiming to provide micronized delivery system for supplement, this may contribute to the 20-35% of the final price.

Quantity to be micronized

Production costs on a large scale tend to be lower than for small batches. This is because the set-up and start-up costs of the process are amortized over a larger number of units or kilograms produced. In a supplement micronization project aiming to provide micronized delivery system for supplement, this may contribute to the 10-30% of the final price.

Quality controls

Micronization can affect the chemical-physical and microbiological characteristics of the final product. Rigorous quality controls are necessary to ensure compliance with specifications and the safety of the final product, in line with European regulations for the marketing of food supplements. The main reference regulations are Directive 2002/46/EC, Regulation (EU) No 1169/2011, and Regulation (EC) No 853/2004. In addition to routine checks, specific analyses are required for micronized supplements, including granulometric, chemical-physical, and microbiological analyses. In a supplement micronization project aiming to provide micronized delivery system for supplement, this may contribute to the 5-15% of the final price.

Saving resources and avoiding mistakes

Now, with a clear price breakdown you can effectively transform the micronization of your supplement from a cost to an investment. To do so you need to define, in the early stage what is your micronization goal. You can read more about supplement micronization goals in this article Spray Drying For Supplements & Nutraceuticals.

Nutritional Value

Stability

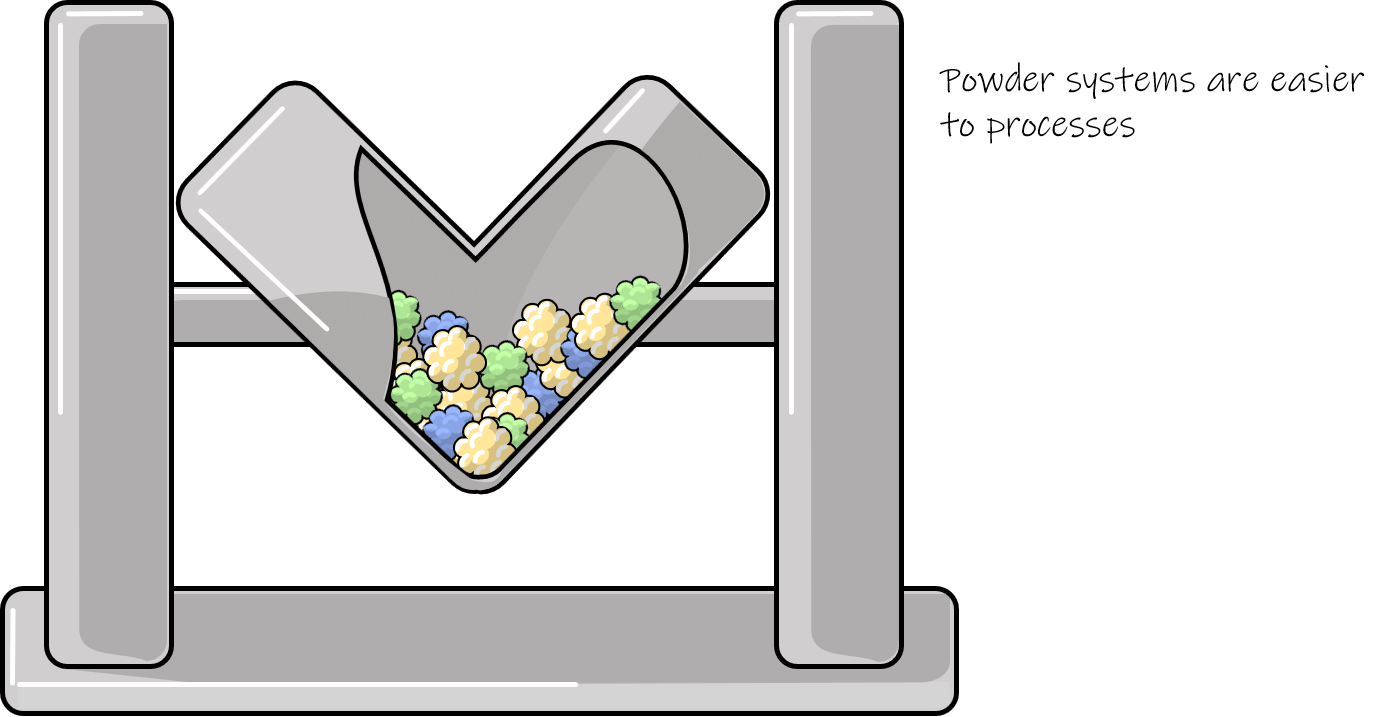

Handling

Bioavailability

Optimizing your supplement micronization

Micronization is an industrial process used to improve one or more of the attribute of a dietary supplement: bioavailability, dispersibility, stability etc of dietary supplements. Depending on which of these attributes is the goal of the micronization the developing and production costs can vary significantly depending on several factors, including:

- The characteristics of the ingredient to be micronized.

- The validation tests.

- The price of the ingredients.

- The pilot production size.

Plan the process in advance

Clearly defining the the goals, the objectives and specifications of the micronized product allows you to optimize the process and reduce costs. At this stage it is important:

- Specify the desired particle size.

Identify the chemical-physical characteristics of the material to be micronized. - Define the quality requirements of the micronized product.

- Estimate the production volume.

Evaluate several prototype alternatives

Imagine you want to create a turmeric-based food supplement. Micronized turmeric offers greater bioavailability than powdered turmeric, but there are several alternatives to the ideal micronized prototype with different characteristics.

Some alternatives offer even greater bioavailability, but the micronization process is more complex and expensive. Other prototypes have similar bioavailability to the standard prototype, but the micronization process is simpler and therefore cheaper.

In this case, it is important to evaluate several aspects:

- What are your goals? If you want to achieve maximum bioavailability, you will have to choose a more expensive prototype. However, if you are willing to settle for a slightly lower bioavailability, you can save money by choosing a cheaper prototype.

- What is your budget? The cost of micronization varies based on the complexity of the process. You will therefore need to choose a prototype that is compatible with your budget.

- What is your target market? If your target is made up of consumers who are willing to pay a higher price for a product with maximum bioavailability, you can choose a more expensive prototype. However, if your target is made up of consumers who are more sensitive to price, you can choose a cheaper prototype.

By evaluating these aspects, you will be able to choose the micronized prototype best suited to your needs and optimize the micronization cost.

Develop a questionnaire to submit to various micronization providers candidates

A well-structured questionnaire allows you to:

- Collect precise and comparable information from different partners.

- Evaluate their experience and expertise in the field of micronization.

- Compare their proposals objectively.

The questionnaire should include questions about:

- The partner’s experience in the micronization process.

- The technologies and processes used.

- Quality control.

- Production costs.

- Delivery times.

- The ability to meet your specific needs.

Request quotes from multiple suppliers

Comparing quotes from different suppliers allows you to get the best price for micronization.

Example of the cost of a micronization project for a food supplement in 2024

Project goal:

Transform a traditional supplement in an advanced product able to make people experience a sensible improvement of their health.

Project objectives:

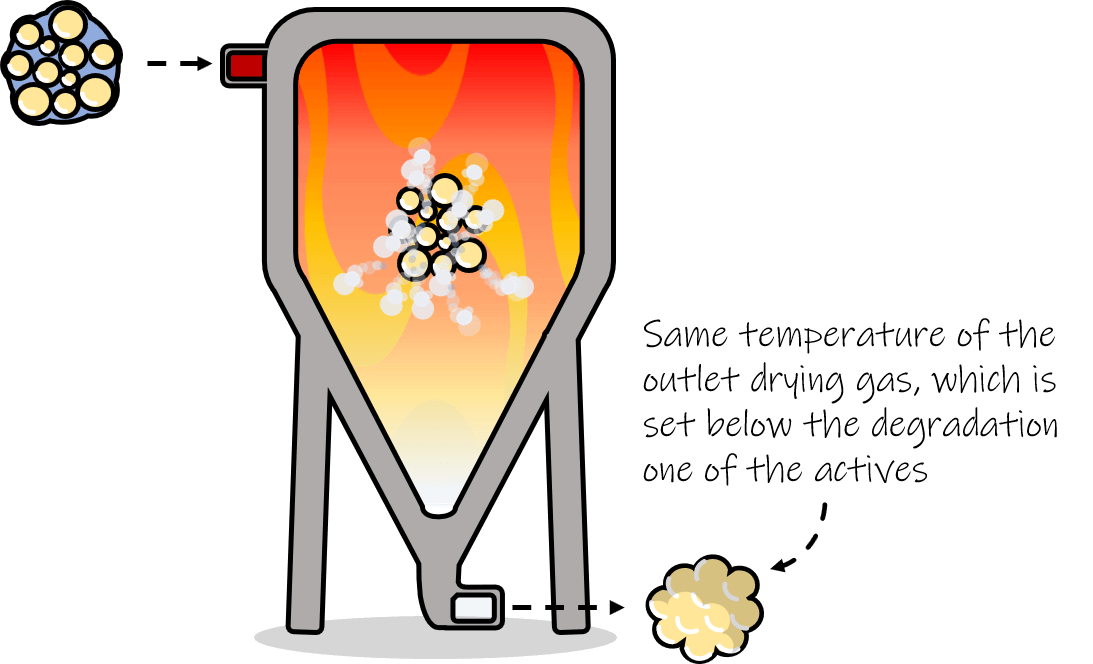

Develop an amorphous powder made of microparticles each acting as an independent delivery system able to:

- Protect the active ingredients from degradation.

- Feature delayed and intelligent release.

- Recognize the pH of the surrounding environment.

- Concentrate the actives in the enteric tract.

Work Package 1

Management

€ 3500

Project planning and management.

Coordination of activities among different partners.

Monitoring of costs and adherence to deadlines.

Risk management.

Communicatrion with the client.

Work Package 2

Development

€ 23000

Selection of the base material for the micro delivery system.

Development of the micronization process.

Optimization of the micronization process.

Characterization of the micronized product.

Efficacy validation testing.

Work Package 3

Industrialization

€ 15000

Shelf-life testing.

Scale-up to large-scale production process.

Quality control of the micronized product.

Pilot production.

Technology transfer to the industrial manufacturer.

Total

€ 41500

Technology Scientific is the SME born as an

academic spin-off

we serve top companies and startups

FREE PDF GUIDE

The Complete Guide to

craft a successful innovation plan for supplement micronization

The ultimate and free guide to easily design an innovation project for supplement micronization, proven to increase the bioavailability and efficacy of your products.

With Technology Scientific supplement micronizations,