Spray Drying Per Integratori e Nutraceutici

Altri articoli sulla micronizzazione:

Siamo specializzati nella micronizzazione di integratori con spray dryer per prodotti ad alta biodisponibilità.

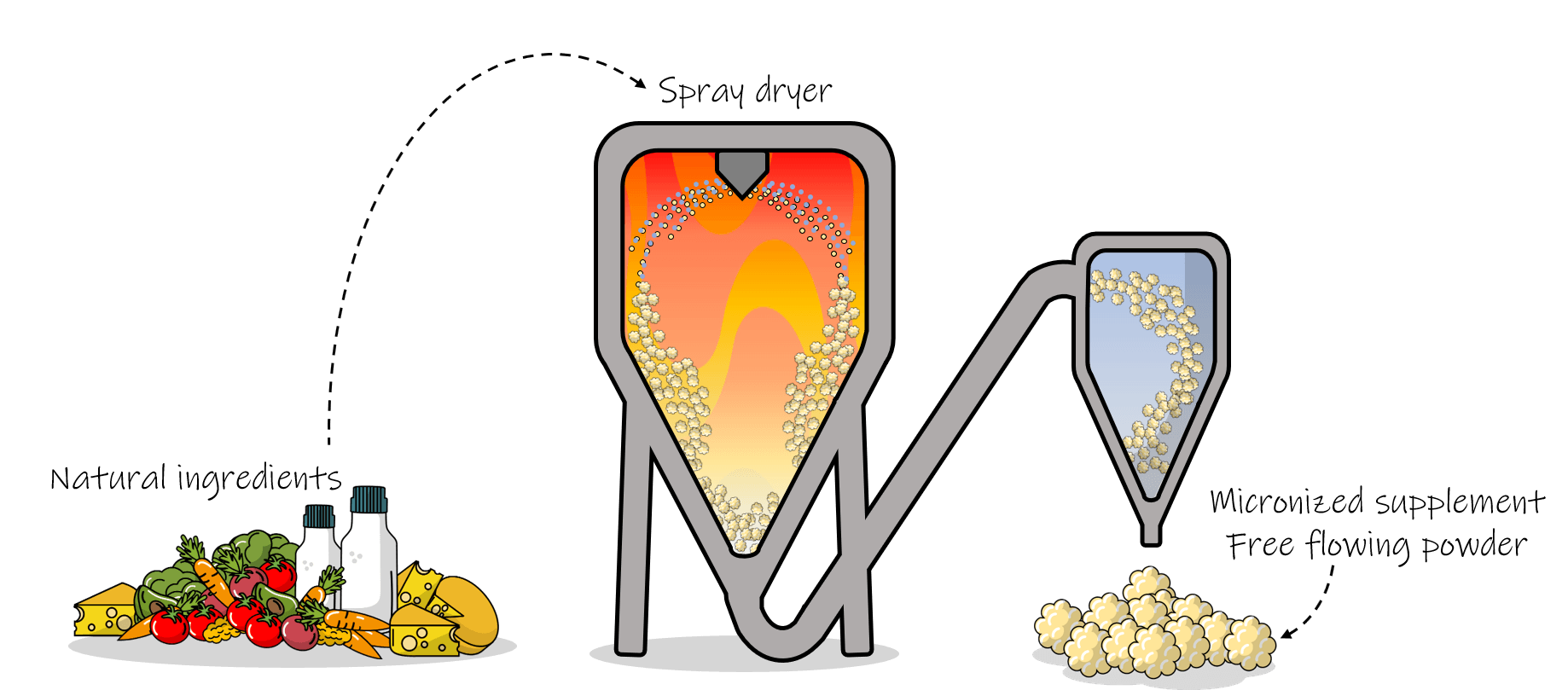

La micronizzazione per spray drying quando applicata a integratori e nutraceutici produce polveri amorfe micronizzate con numerosi vantaggi che vanno da una maggiore flessibilità produttiva a una maggiore biodisponibilità ed efficacia. Questo articolo fornisce una panoramica dei concetti di base, delle considerazioni chiave e dei vantaggi dell’essiccazione a spruzzo per gli integratori.

In questo articolo, i vantaggi della micronizzazione con spray dryer per integratori e nutraceutici

Vantaggi dello spray drying per gli integratori

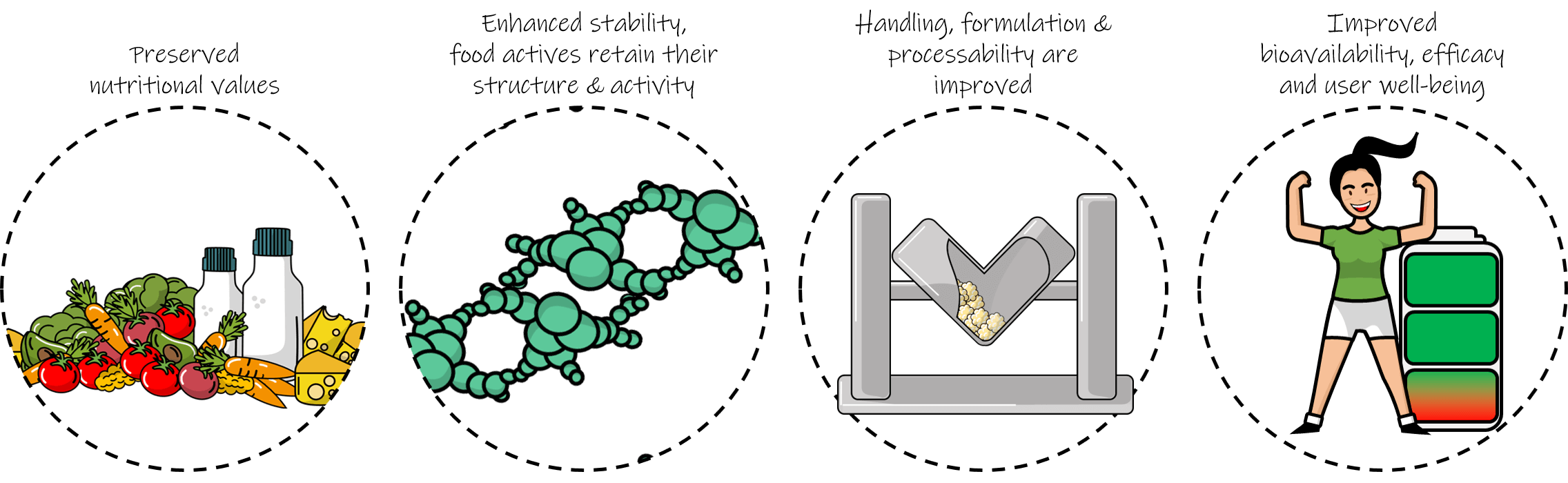

1. Conservazione del valore nutrizionale

2. Stabilità migliorata

3. Maggior flessibilità di conservazione e formulazione

4. Migliore solubilità e biodisponibilità

Conservazione del valore nutrizionale

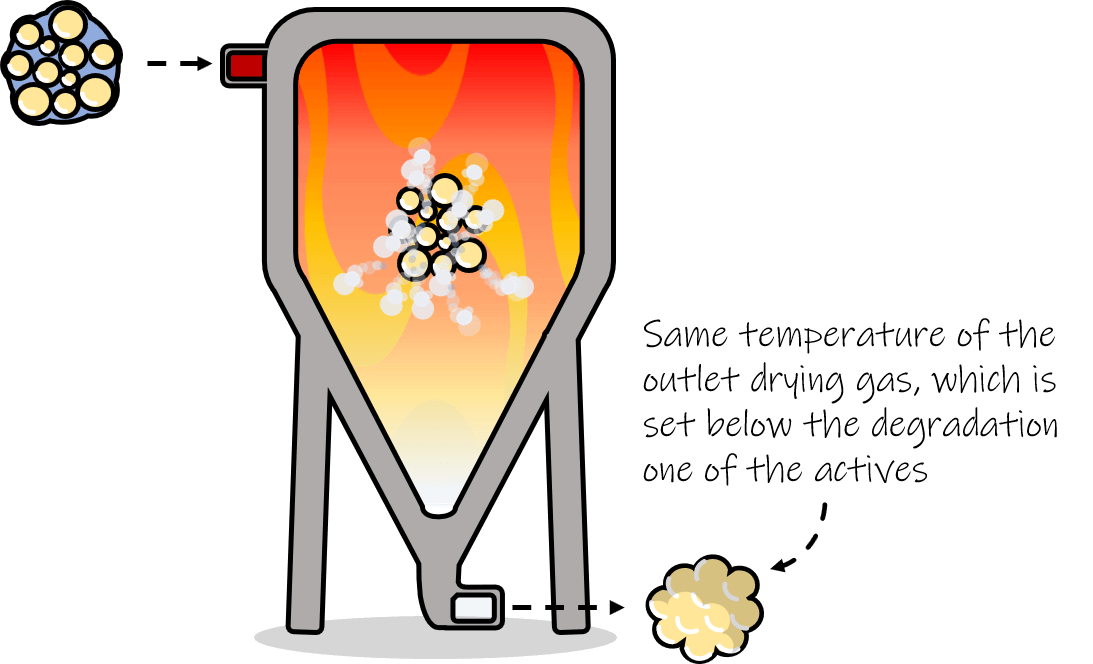

Il processo di essicazione per spray drying riduce al minimo la degradazione di composti attivi termolabili, come vitamine, antiossidanti ed enzimi, preservandone l’attività biologica e il valore nutrizionale. All’interno della camera di essiccazione il liquido di alimentazione viene atomizzato in goccioline microscopiche ed esposte alle alte temperature del gas in entrata. Il calore viene utilizzato dalla fase liquida delle goccioline per un cambio di stato liquido-gas. La componente solida delle goccioline si aggrega a la sua temperatura tende ad eguagliare quella del gas in uscita, che sarà impostata al di sotto di quella denaturazione dei composti solidi per preservarne i benefici salutistici.

Stabilità migliorata

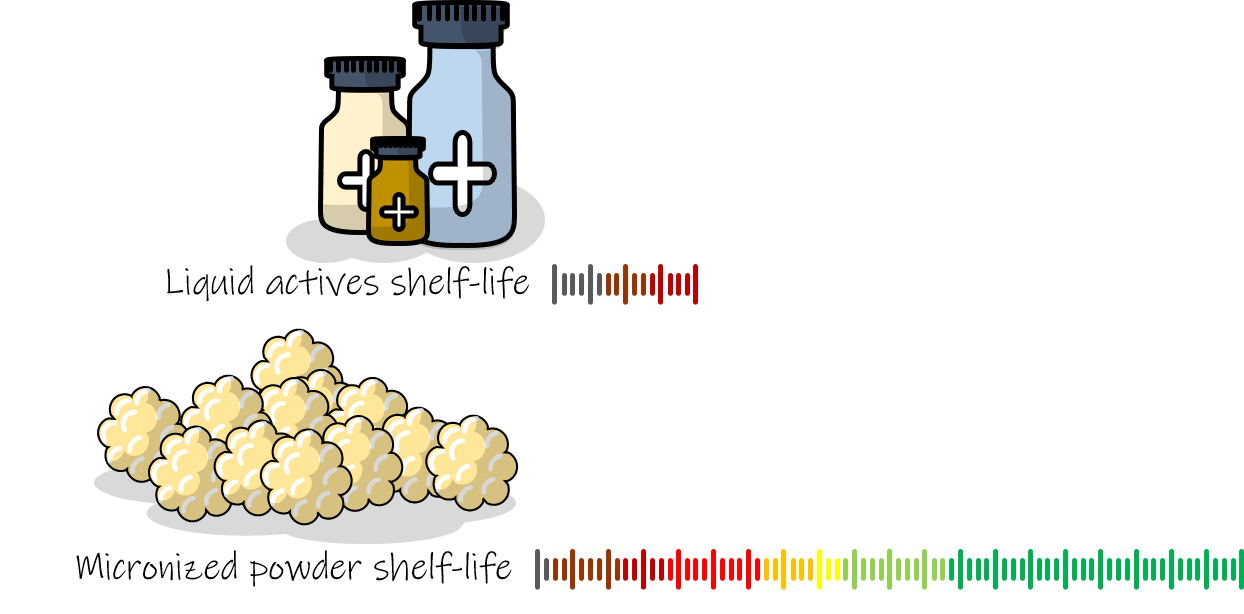

Lo spray drying converte gli integratori liquidi in polveri secche con una aw (water activity) sotto 0.05, migliorandone significativamente la loro stabilità e prolungandone la durata e riducendo il rischio di deterioramento, ossidazione o crescita microbica.

Maggior flessibilità di conservazione e formulazione

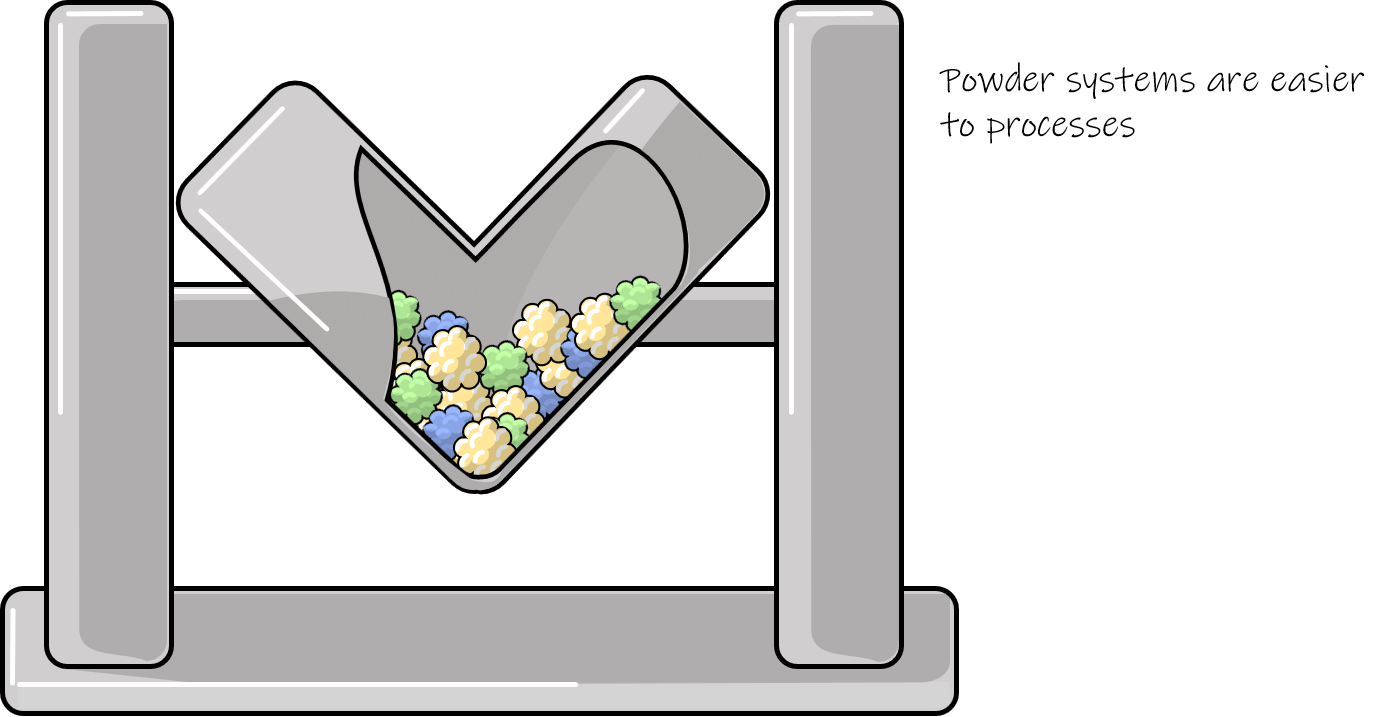

Lo spray drying produce integratori in forma di polveri migliorandone la manipolazione nelle ulteriori fasi di formulazione e lavorazione come miscelazione, compressione e incapsulamento.

Migliore solubilità e biodisponibilità

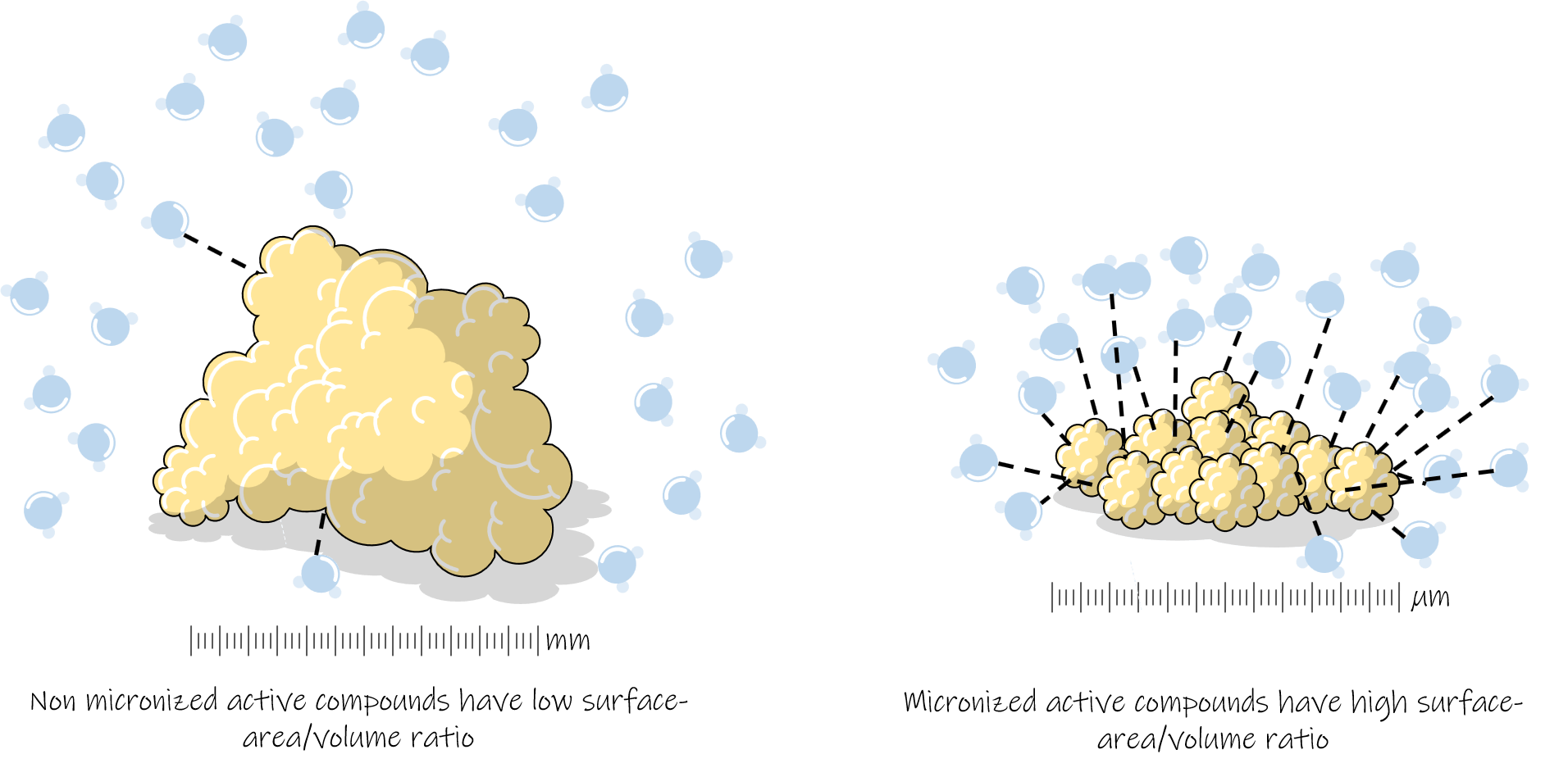

Gli integratori micronizzati con spray drying posseggono un maggior efficacia. L’elevato rapporto area superficiale/volume facilità la liberazione dei principi attivi e quindi ne aumenta la concentrazione sia nel sito di assorbimento che nel torrente ematico ( biodisponibilità ).

Conclusione

Lo spray drying è una tecnica che aumenta il valore e l’efficacia degli integratori. La comprensione dei suoi concetti di base consente l’ottimizzazione del processo termodinamico, costanza della qualità e costi di produzione razionalizzati.

Technology Scientific è la PMI nata spin-off Serviamo le migliori aziende e startups

GUIDA PDF GRATUITA

La guida completa alla

progettazione di processi di micronizzazione di integratori

La guida definitiva e gratuita per progettare,

realizzare e lanciare il tuo integratore micronizzato.

Con le micronizzazioni di Technology Scientific,