Spray Drying For

Supplements & Nutraceuticals

Other articles about micronization:

We are experts of in micronization of supplements and micro delivery systems for supplements with high bioavailability.

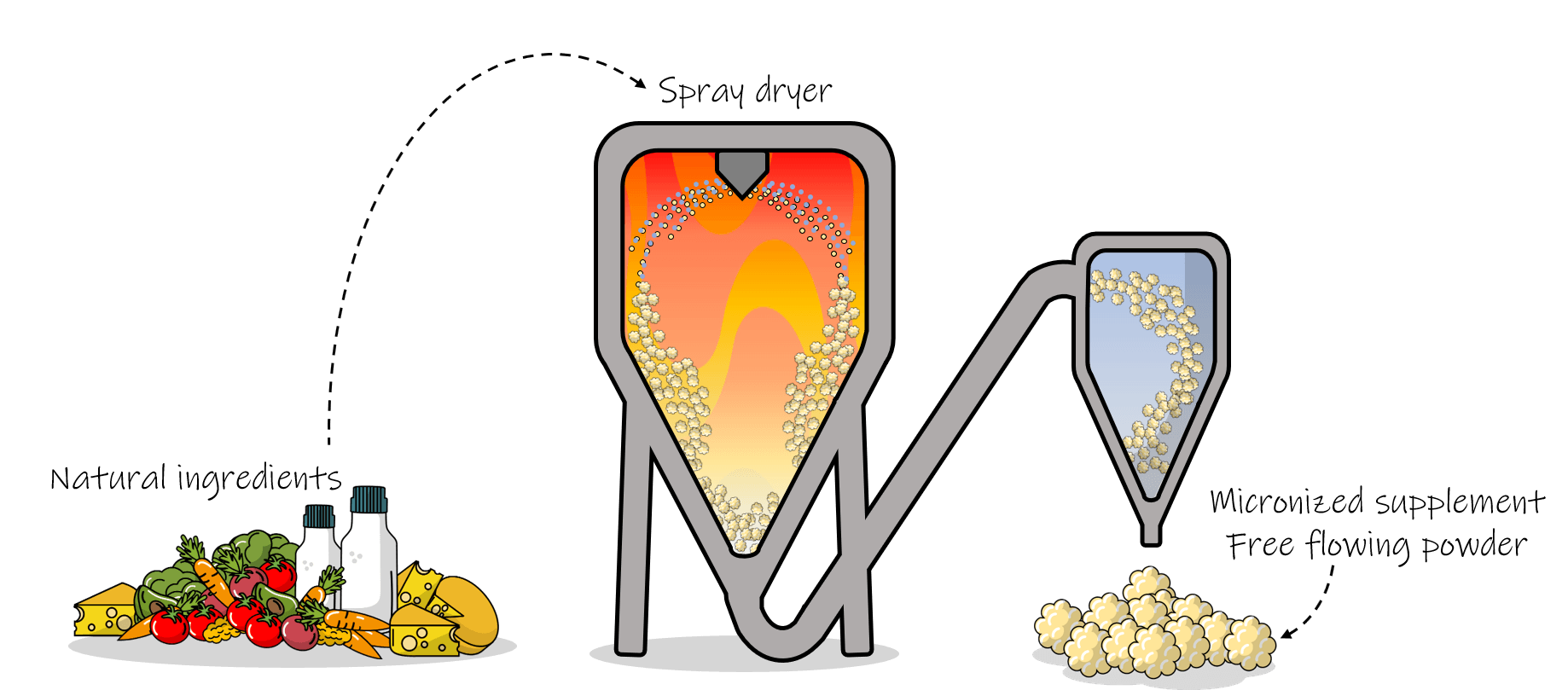

Spray drying when applied to supplements and nutraceuticals produces micronized amorphous powders featuring incredible advantages ranging from higher production flexibility to increased bioavailability and efficacy. This article provides an overview of the basic concepts, key considerations, and benefits of spray drying for supplements.

In this article, we'll outline the steps during the micronization with spray dryer of supplements.

Benefits of Spray Drying Micronization for Supplements

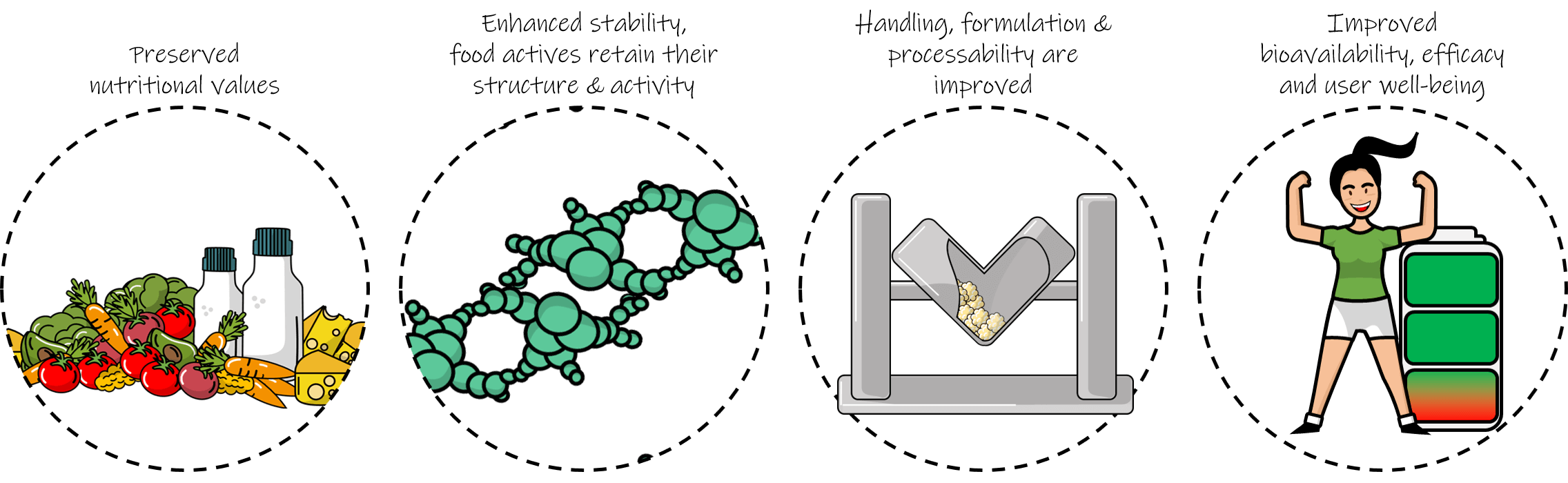

- Preservation of Nutritional Value

- Enhanced Stability

- Convenient Handling and Formulation

- Improved Solubility and Bioavailability

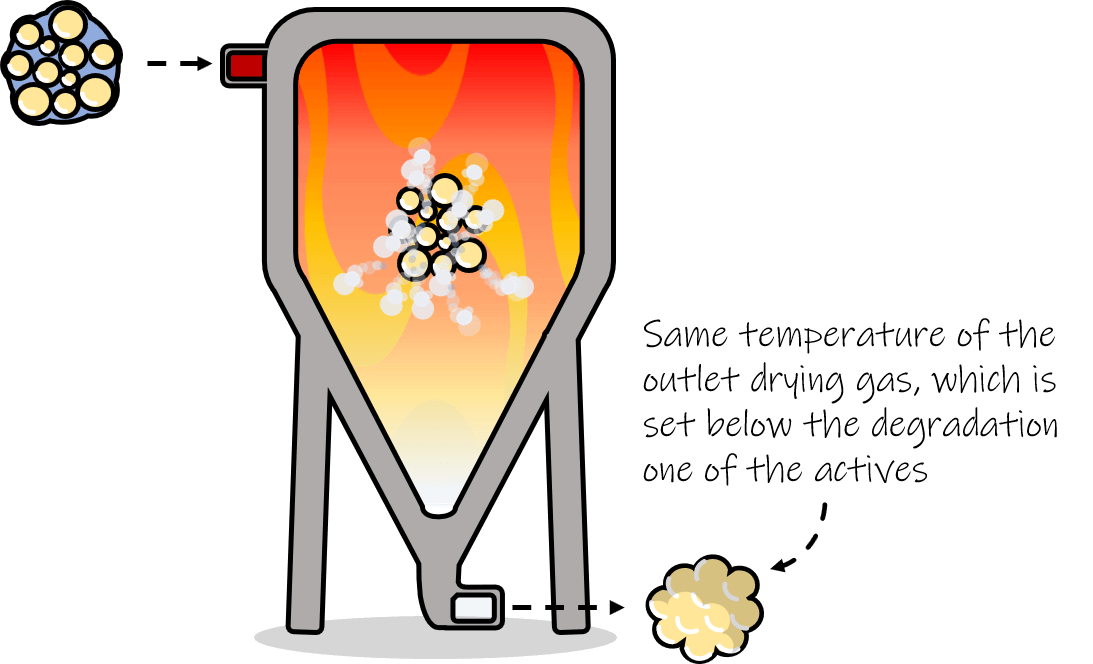

Preservation Of The Nutritional Value

Spray drying is a gentle transformation process for degradation sensitive compounds, preserving their biological activity and nutritional value. During the liquid evaporation active compound temperature increase up to match that of the outlet gas. When this is set below the denaturing one of the active compounds their structure, activity and health benefits are preserved.

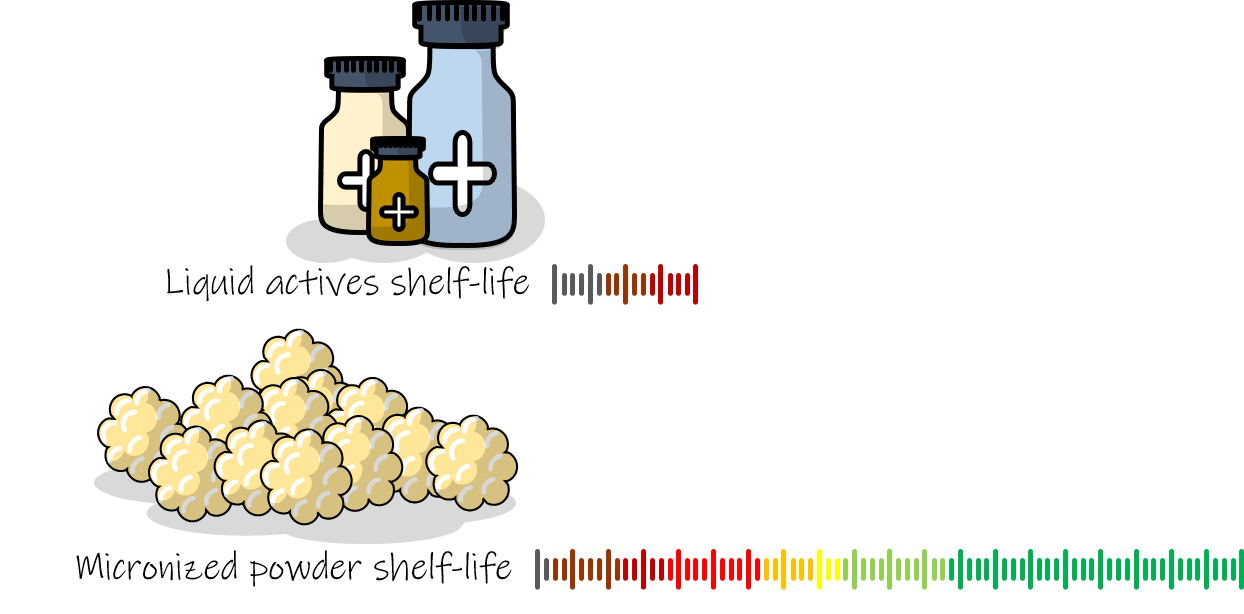

Enhanced Stability

The conversion of liquid supplements into powders significantly improves their stability, extending their shelf life and reducing the risk of spoilage, oxidation, or microbial growth.

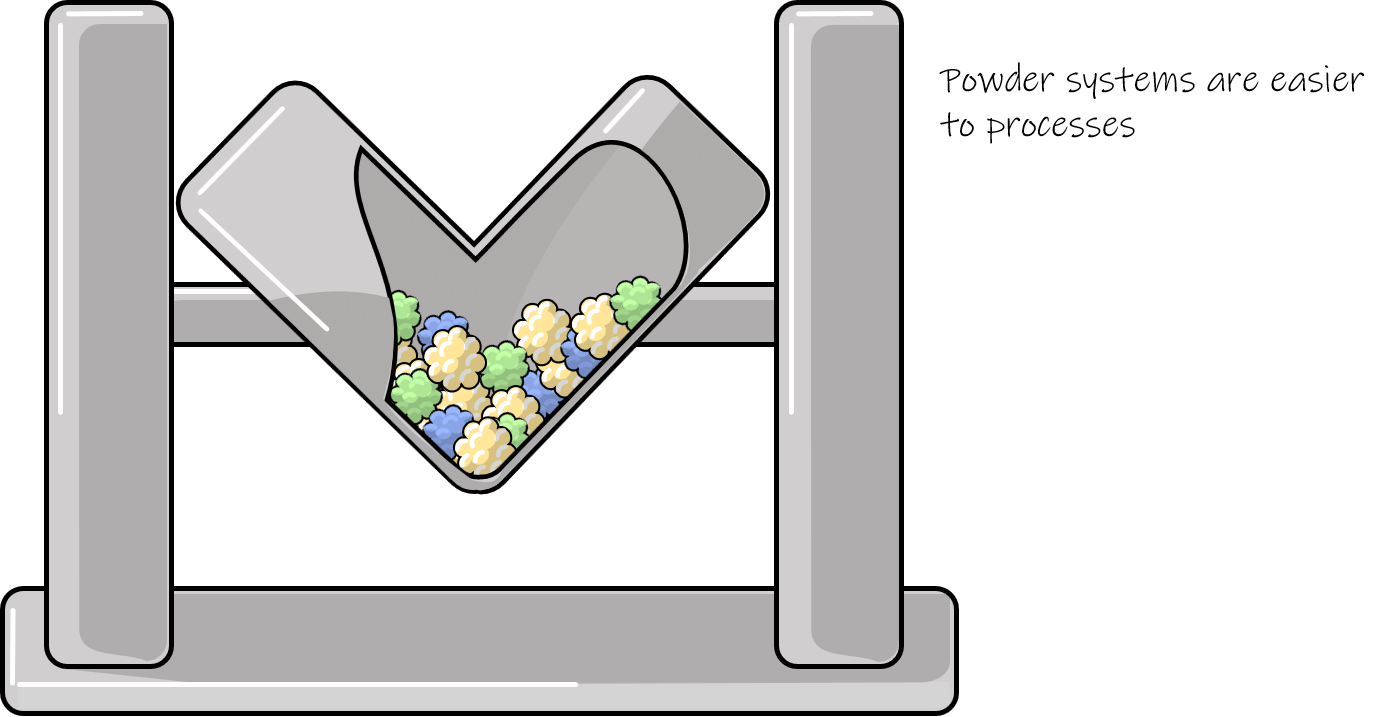

Convenient Handling and Formulation

Powdered supplements produced by spray drying are easy to handle, measure, and mix, allowing for convenient formulation of capsules, tablets, or powdered drink formulations.

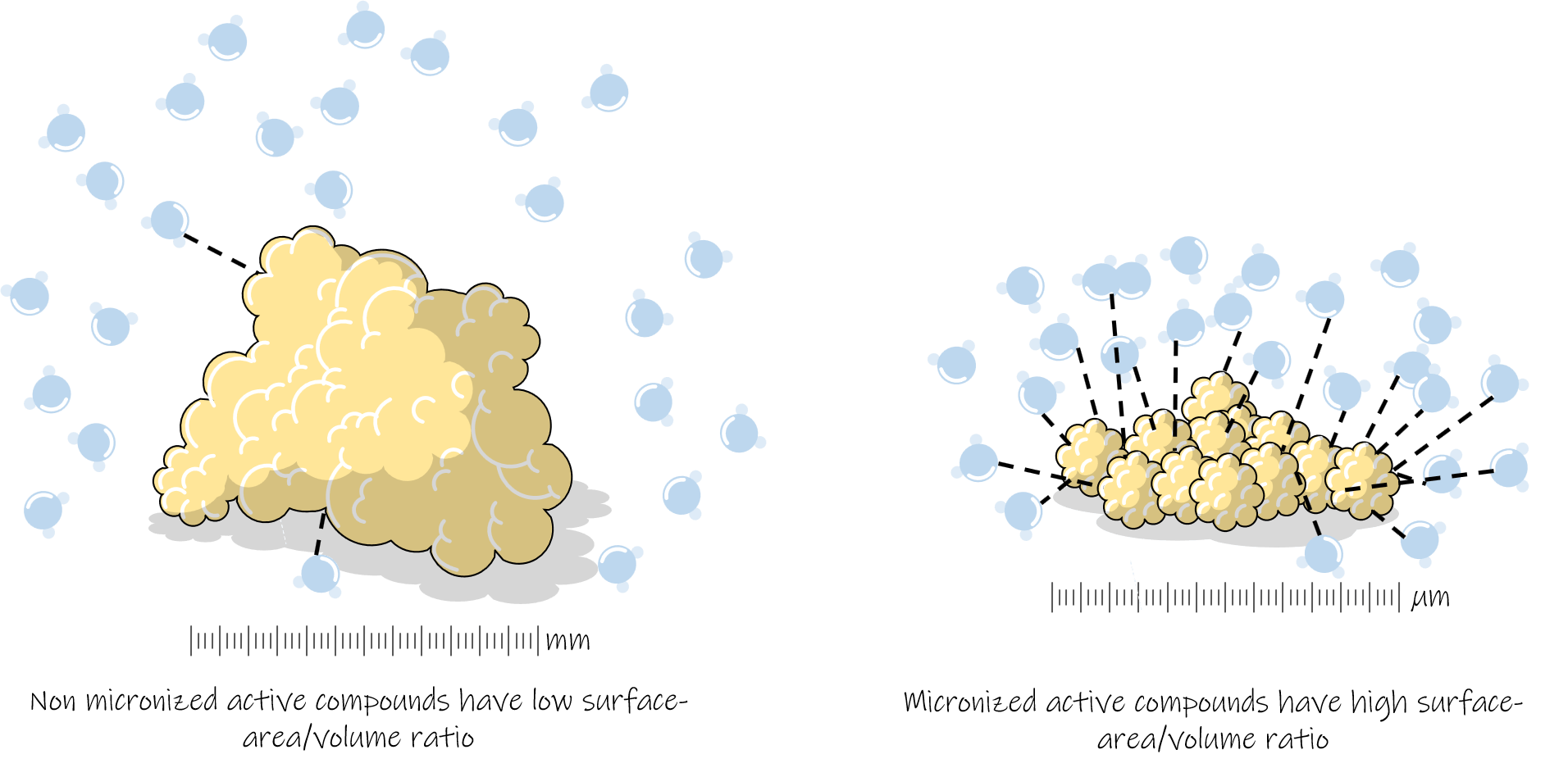

Improved Solubility and Bioavailability

Spray-dried powders often exhibit improved solubility and dispersibility, enhancing their bioavailability and ensuring efficient absorption by the body.

Conclusion

Spray drying is a valuable technique in the production of powdered supplements. By understanding the basic concepts behind spray drying, including the process steps, key considerations, and benefits, manufacturers can optimize their supplement formulations and achieve desirable product characteristics.

Technology Scientific is the SME born as an

academic spin-off

We serve top companies and startups

top companies and startups

FREE PDF GUIDE

The Complete Guide to

craft a successful innovation plan for supplement micronization

The ultimate and free guide to easily design an innovation project for supplement micronization, proven to increase the bioavailability and efficacy of your products.

With Technology Scientific micronization,